- Applications

- Methods

- Equipment

- View All Equipment

- Guided Boring

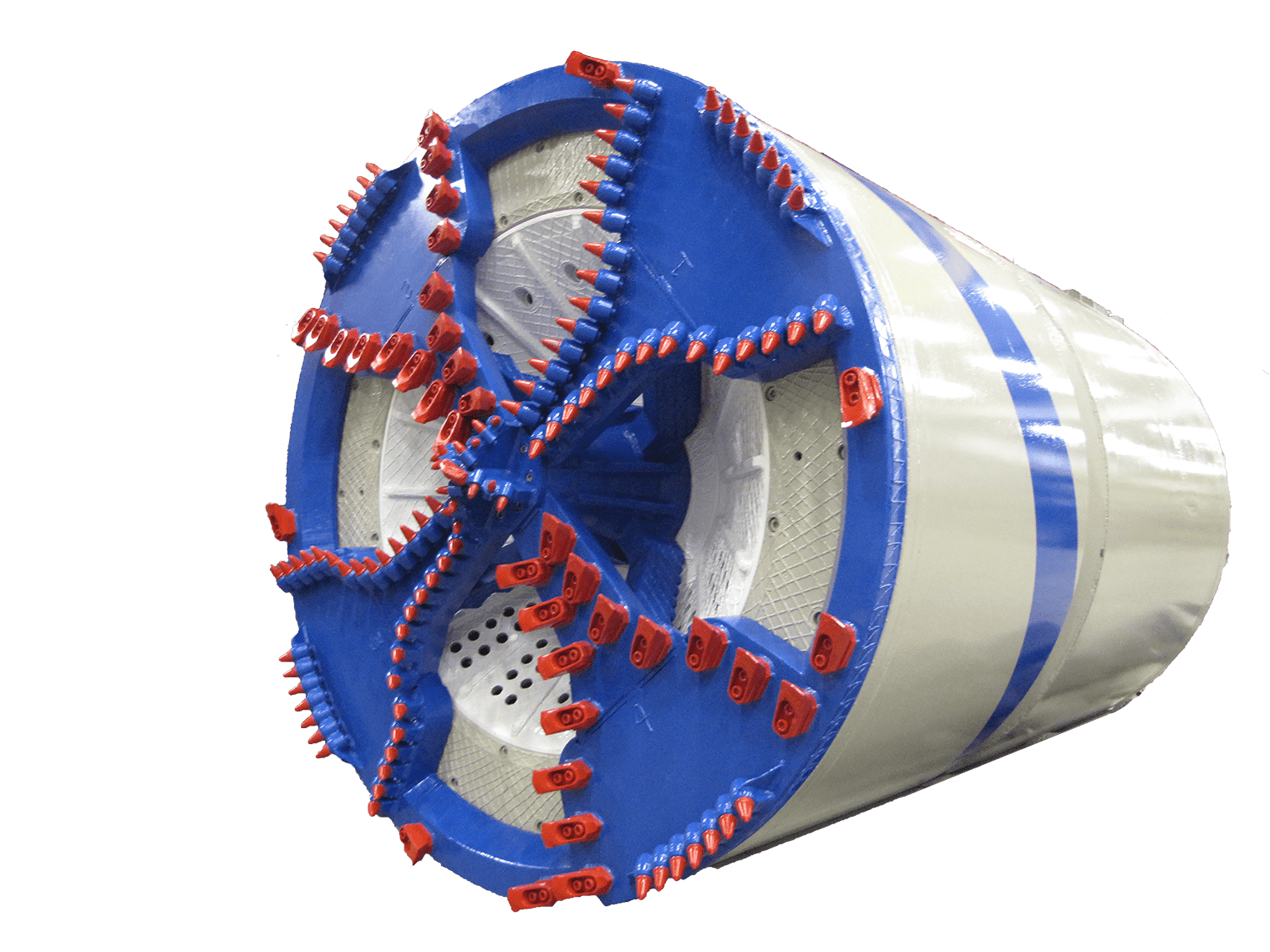

- Slurry Microtunneling

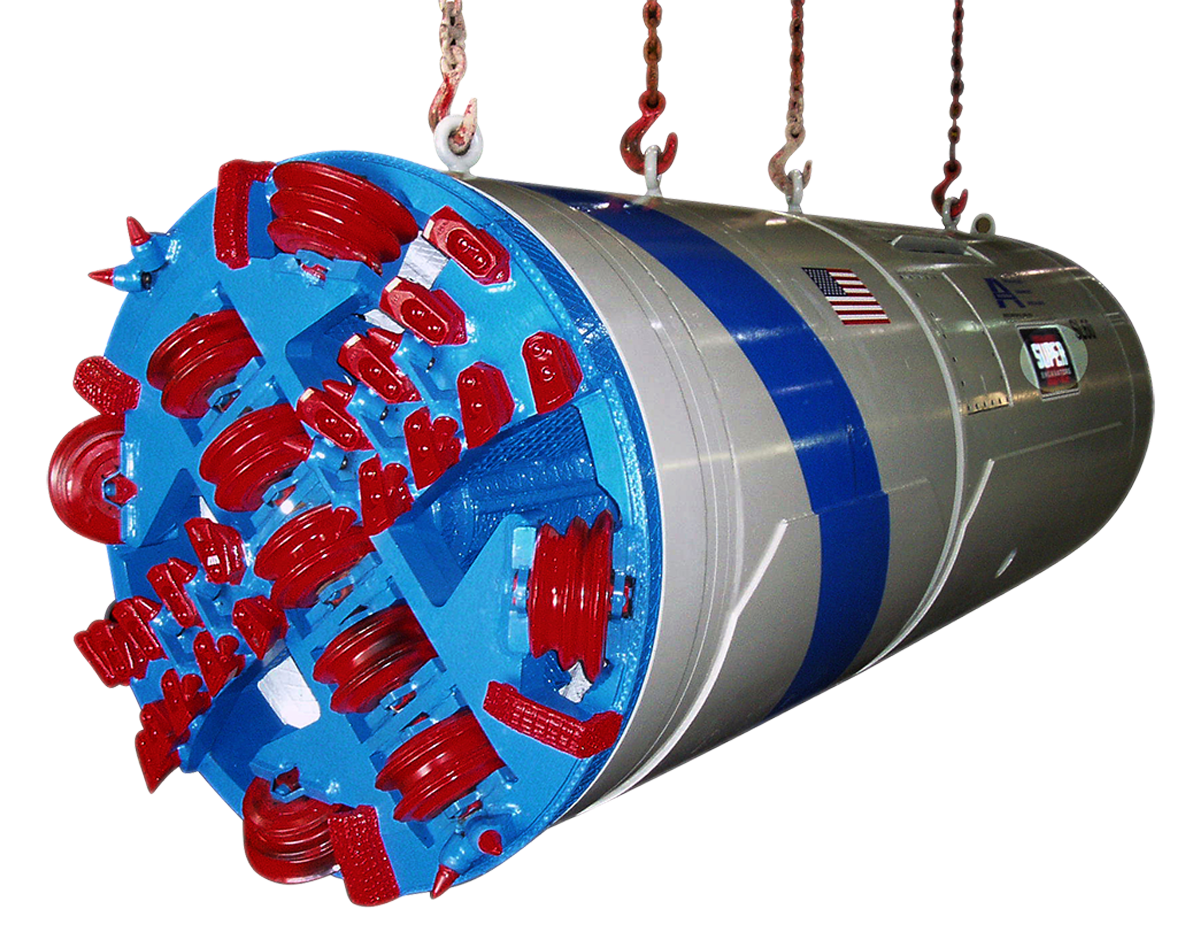

- SLC Series System – Center Drive

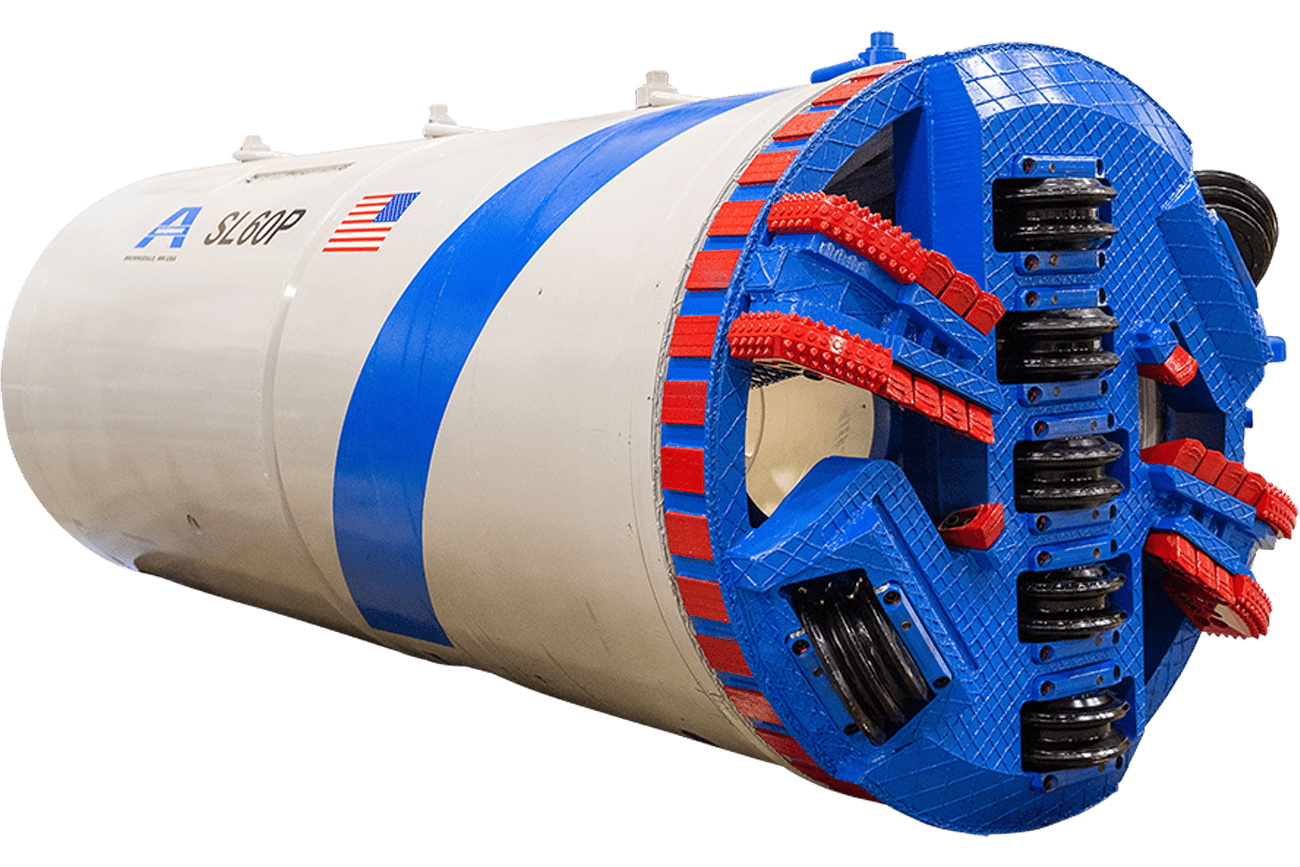

- SLP Series System – Periphery Drive

- Control Containers

- MTBM Guidance System

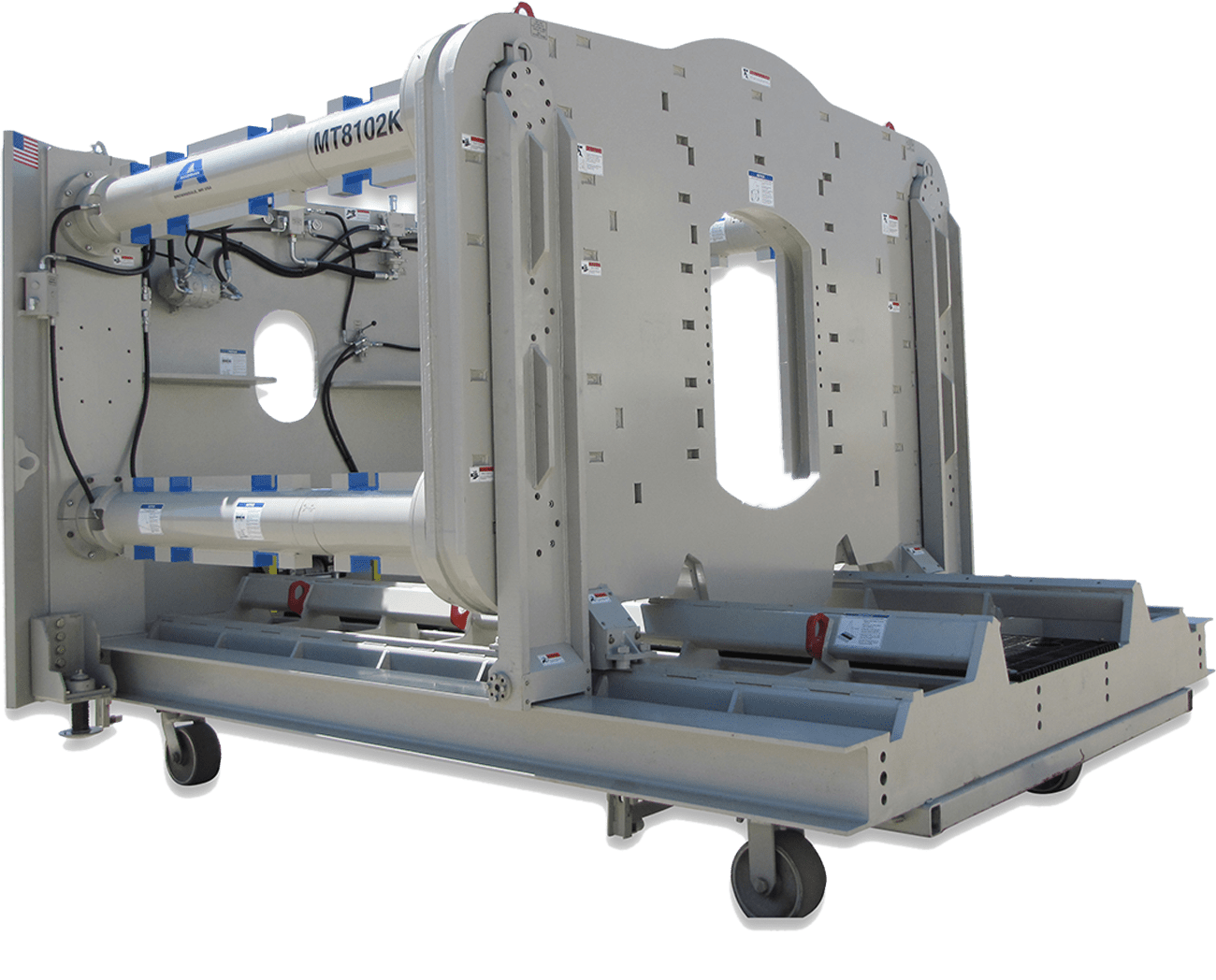

- MTBM Jacking Frames

- MTBM Increase Kits

- MTBM Lubrication & Jacking Cans

- Automated Bentonite Injection System

- MTBM Intermediate Jacking Stations

- Shaft Seals & Pipe Clamps

- Water Jetting & Cooling

- AZ100 Total Guidance System

- Pipe Jacking & Utility Tunneling

- Sliplining

- Lubrication Systems

- Support Equipment

- Case Studies

- Parts & Services

- Sales & Leasing

- Financing

- Contact