Akkerman Earth Pressure Balance Machines (EPBM) are designed for soft, wet, or unstable, pressurized ground under the water table. Akkerman EPBM equipment is manufactured to pipe jack prefabricated jacking pipe or install liner plate, rib and board, or steel liner plate.

EPBM systems for large infrastructure projects are custom designed and manufactured.

Features:

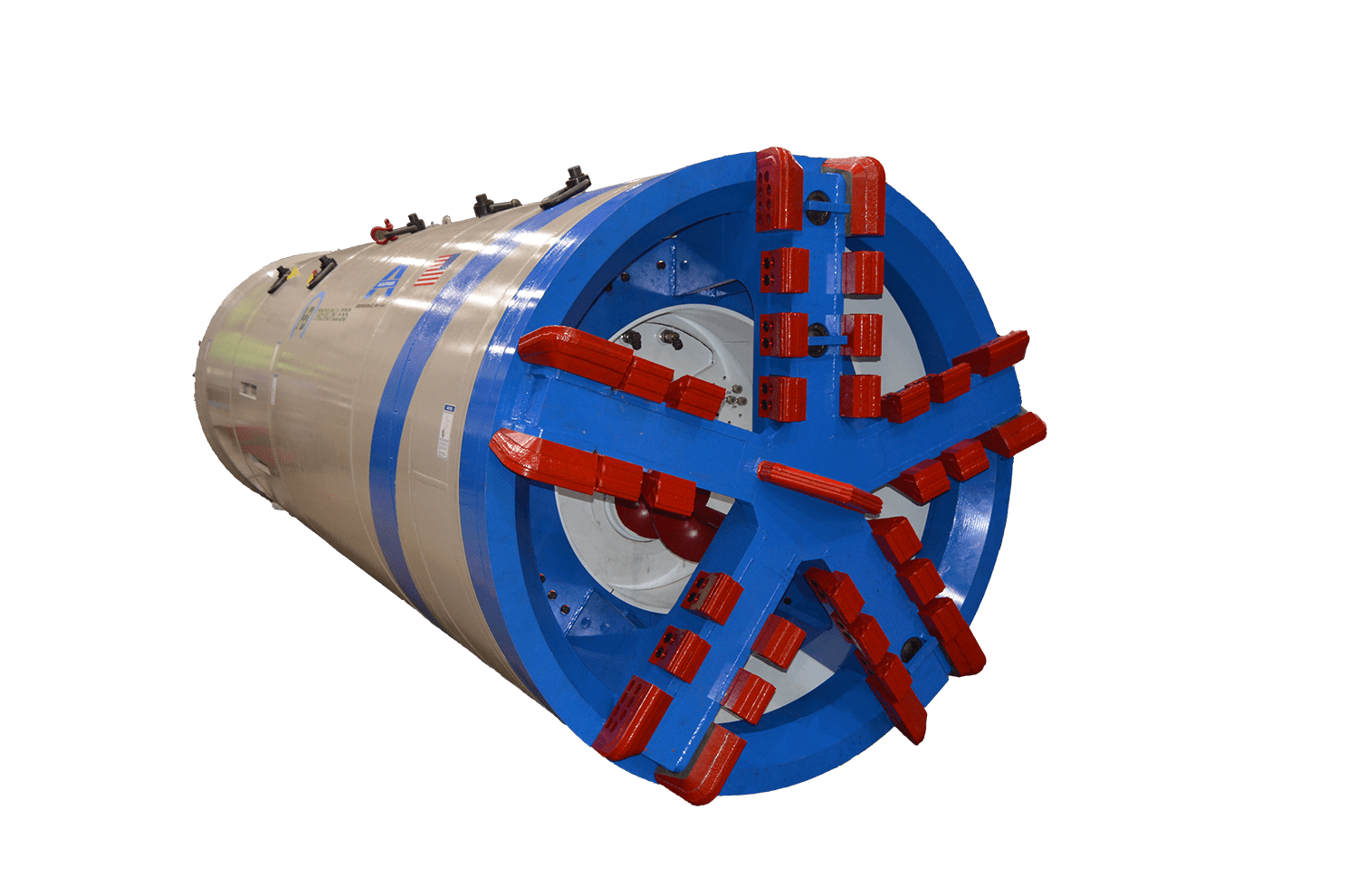

- Cutter Heads and Tooling – Our EPBMs are customized with soft ground cutting heads with carbide embedded tooling or mixed‐face designs that incorporate roller disc cutters and soft ground tooling.

- Plenum Mixing Chamber – The Plenum Chamber mixes the spoils and allows the operator to inject conditioning slurry directly behind the cutter head.

- Earth Pressure Sensors – Dual earth pressure sensors on the plenum communicate the chamber pressure to the EPBM operator.

- Sealed Steering System – Active articulation for line and grade control in combination with a sealed steering joint.

- Primary Screw Conveyor – The EPBM uses a variable speed primary screw conveyor to adjust the spoil removal rate from the plenum chamber. The conveyor speed is dependent on the rate of advancement of the EPBM and earth pressure in the plenum chamber.

- Main Bearing and Drive System – Akkerman EPBM systems utilize heavy‐duty tri‐roller TBM bearings with grease purged bearing seals. Our Hydraulic periphery drive system offers variable speed control with high torque output.

- Guidance System – Akkerman EPBM systems can accommodate a variety of guidance systems depending on the application. For pipe jacking, a standard tunnel laser with an active target system is often used. Extended distances, curved tunnels, and ring building systems utilize total station, prism‐based navigation control systems.

- Additional Accessories – A variety of complementary accessories are available for your project requirements.

Earth Pressure Balance Machine (EPBM)

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.