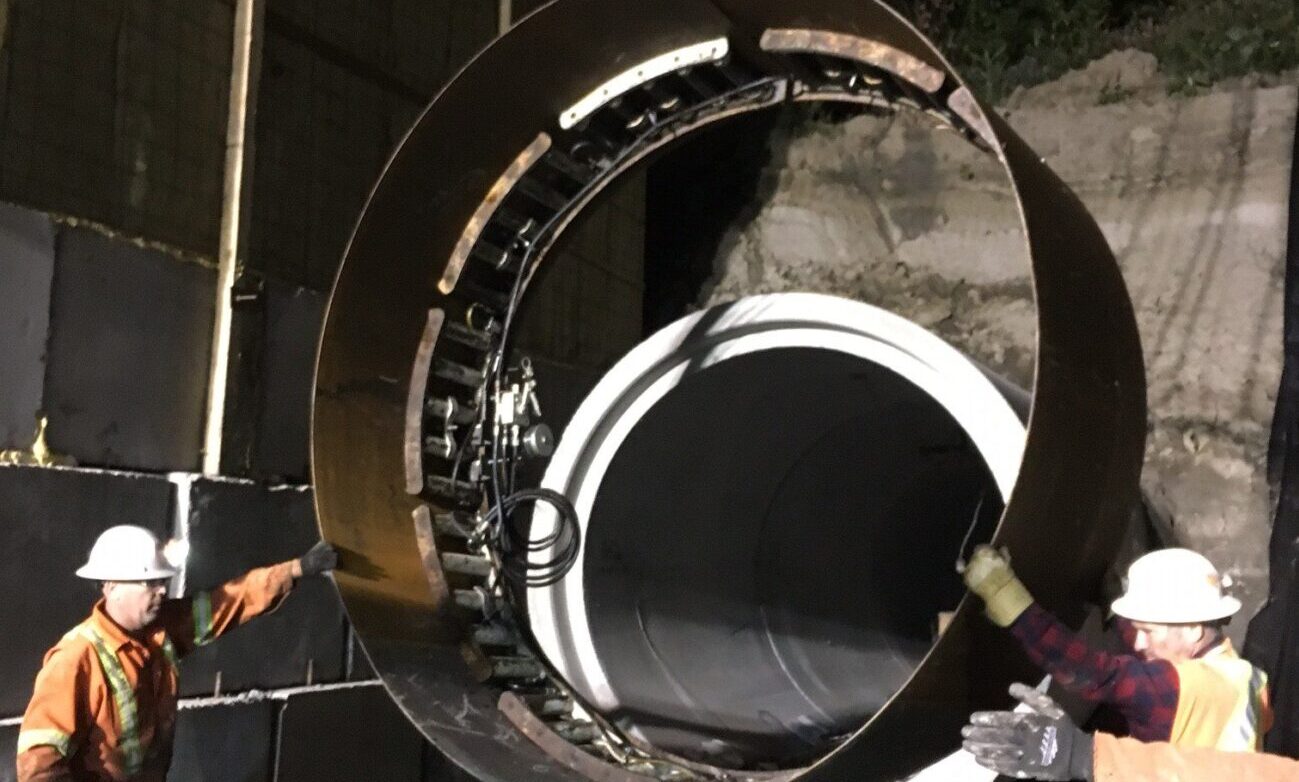

Intermediate Jacking Stations (IJSs) as inserted in the tunnel string at appropriate intervals to enhance and distribute thrust loads and facilitate longer drives. IJSs are designed to match a project’s exact pipe outside diameter. IJSs are custom built to match common RCP, steel casing, or CCFRPM pipe joints.

An IJS is recommended when the thrust pressure reaches one‐third of the pump unit’s maximum pressure capacity or half of the IJS thrust capacity. The IJS assembly comprises a non‐recoverable steel housing with multiple ram segments that each exerts additional thrust and is positioned on the steel housing’s interior ring.

IJS cylinders are controlled by the pump unit operator with a line holder cable, connected to hydraulic hoses and spool valves in the tunnel. IJS function can also be controlled through the ABIS system Monitor for automated injection.

Features:

- Used to extend drive length potential by distributing thrust load for longer drives

- Sealed to prevent intrusion of ground into the tunnel

- Comprise a non‐recoverable steel housing with multiples of ram segments that each exert additional hydraulic pressure

- Customized to match the outside diameter of the project pipe

Intermediate Jacking Stations (IJSs)

Specifications

IJS

| Length of Stroke Cylinders | Qty. of Thrust Rams | Capacity Per Ram @ 8,000 psi |

|---|---|---|

| 7‐in. | 5‐18 Segments | 55‐tons |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.