Navigation control is one of the most critical elements for successful microtunneling. Design criteria installation accuracy is maintained using active laser guidance systems.

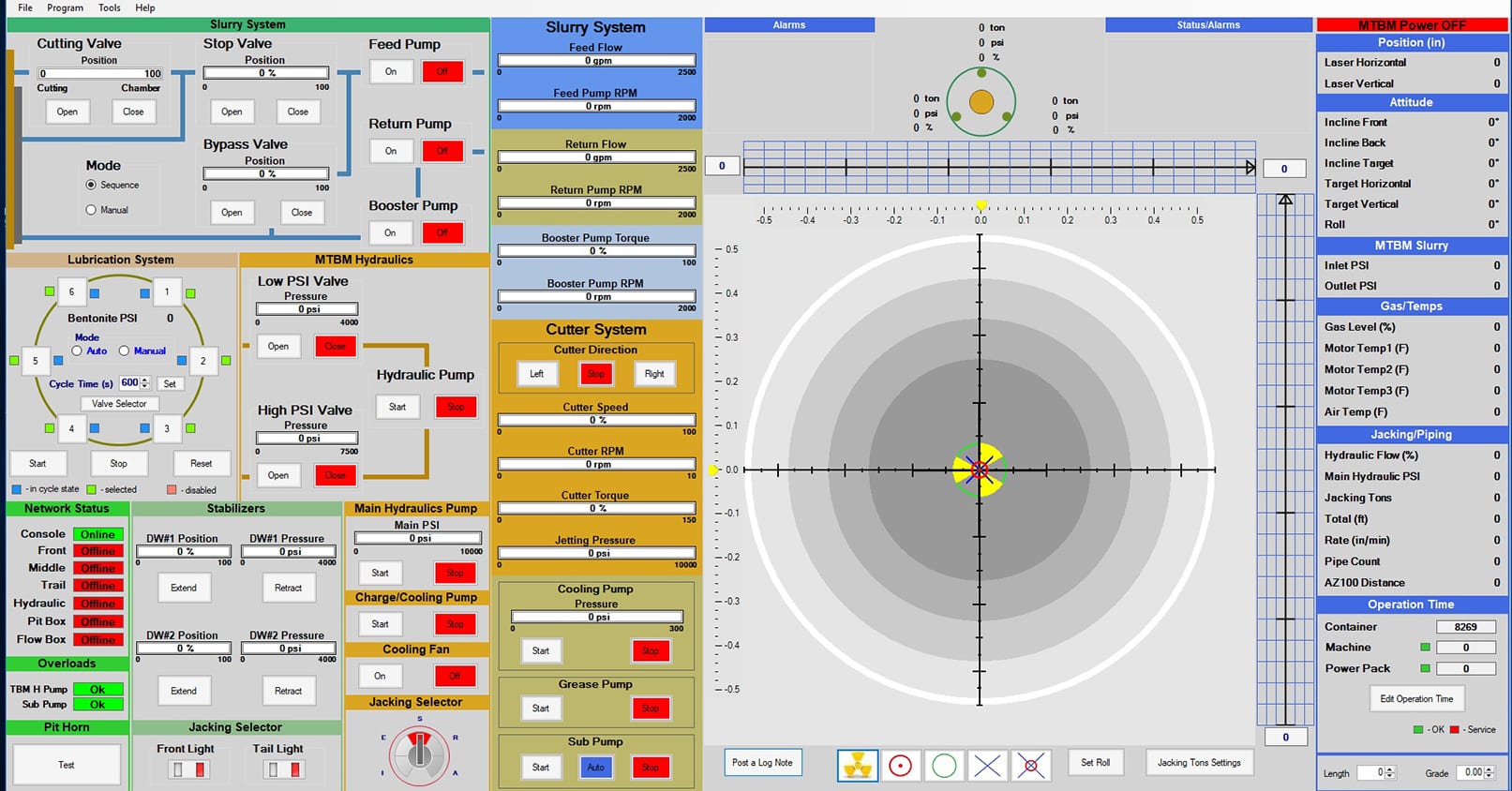

A shaft station reference laser is positioned on line and grade behind the jacking frame and protected from disturbance. The laser is projected down the tunnel onto the MTBM’s active target at the design’s line and grade. The MTBM contains three inclinometers read and transmit the MTBMs pitch, yaw, and incline data coordinates. Target sensors relay this data to where it is numerically displayed on the operator’s control console.

Features:

- Light sensitive TGS100 active target reads the laser beam and transmits x and y coordinates and MTBM incline to the control console interface

- Reads the location of the most intense light

- Two redundant inclinometers to measure MTBM pitch and roll

- Target display screen displays current and projected cutter head position

- System logs over 100 data points for customized reporting to track and graph alignment deviation, face pressure, and torque changes.

Microtunneling Guidance System

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.