The GBM 240A is the industry-leading pilot tube system for accurately guiding horizontal auger bore equipment. With hundreds of systems being used globally, industry leaders rely on the accuracy and versatility that the 240A adds to their trenchless toolbox.

Features:

- Establish line and grade accuracy critical for gravity flow installations.

- Adjustable base frame adapter fits all major auger bore machines.

- Minimize project cost by reduced casing diameter requirements.

- Achieve longer auger bore installations with straight alignments.

- Avoid tripping augers to survey alignment and adjust for deviations during standard boring.

- Probe for obstructions or detail changing ground conditions along the alignment during the pilot tube installation.

- Utilize for several other trenchless installations such as guided pipe ramming, guided reaming, probing, pipe roofing, foundation securing, geothermal, etc.

- Utilize as a stand-alone system in a 10-ft shaft to direct install product pipe up to 24in OD.

- Installs pilot tubes in a wide range of ground conditions including rock.

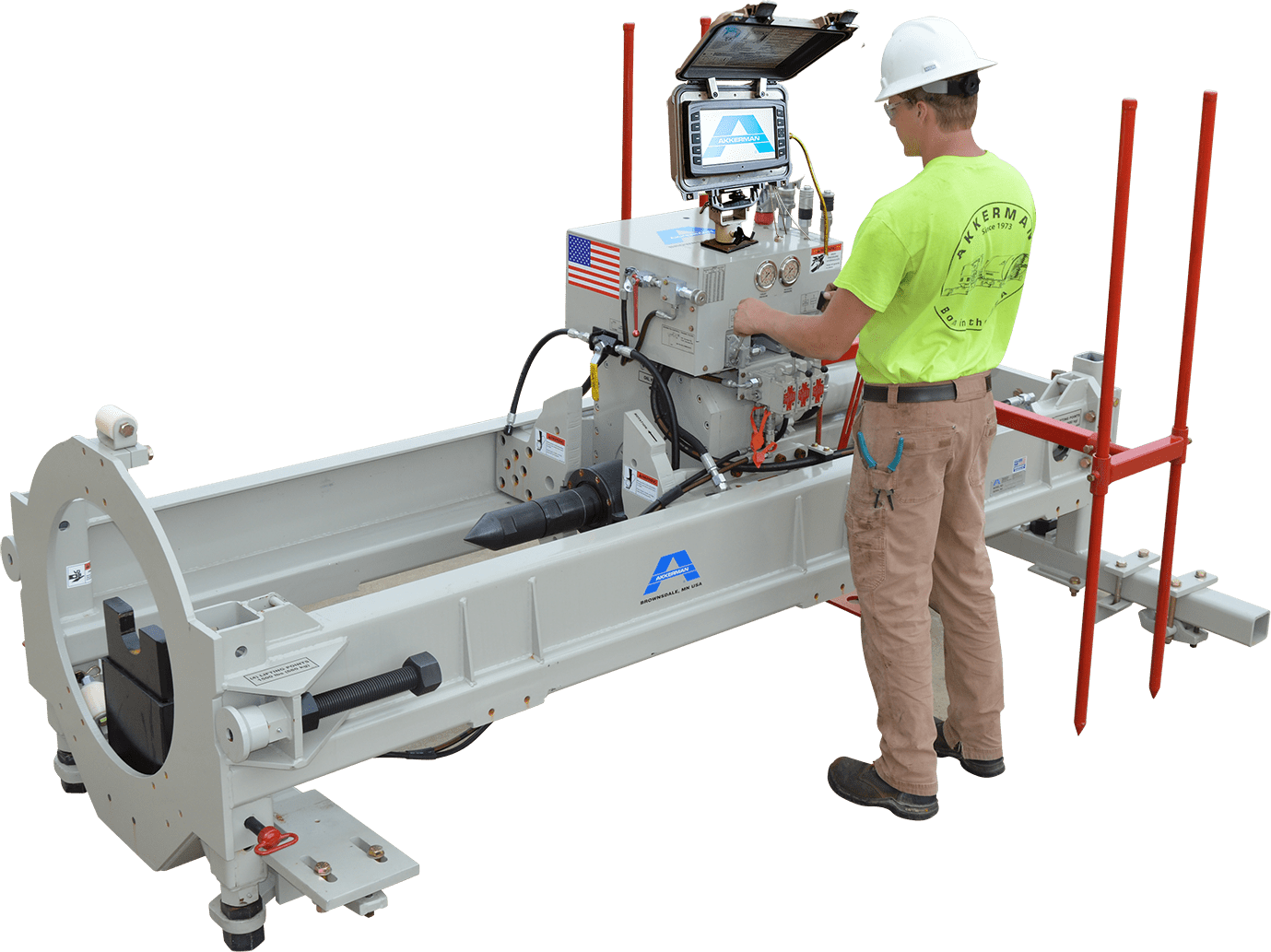

GBM 240A Jacking Frame

Specifications

| Model | Torque | Thrust/Pullback | Weight |

|---|---|---|---|

| 240A | 10,500 ft-lbs. | 100/50 ton | 4,500‐lbs. |

| Model | HP | Hydraulic | Control |

|---|---|---|---|

| P4075D | 75hp Diesel | (2) – Variable Piston | Remote Pendent |

| P100E | 100hp Electric | (2) – Variable Piston | Remote Pendent |

| Model | HP | Pump | Capacity |

|---|---|---|---|

| 1525B/D | 20hp Diesel | 10gpm / 2,500 psi | 525 gal. |

| 1525B/E | 20hp Electric | 10gpm / 2,500 psi | 525 gal. |

| 1325B/G | 14hp Gas | 6gpm / 2,500 psi | 325 gal. |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.