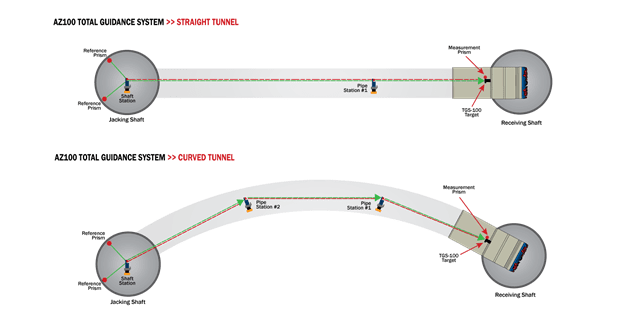

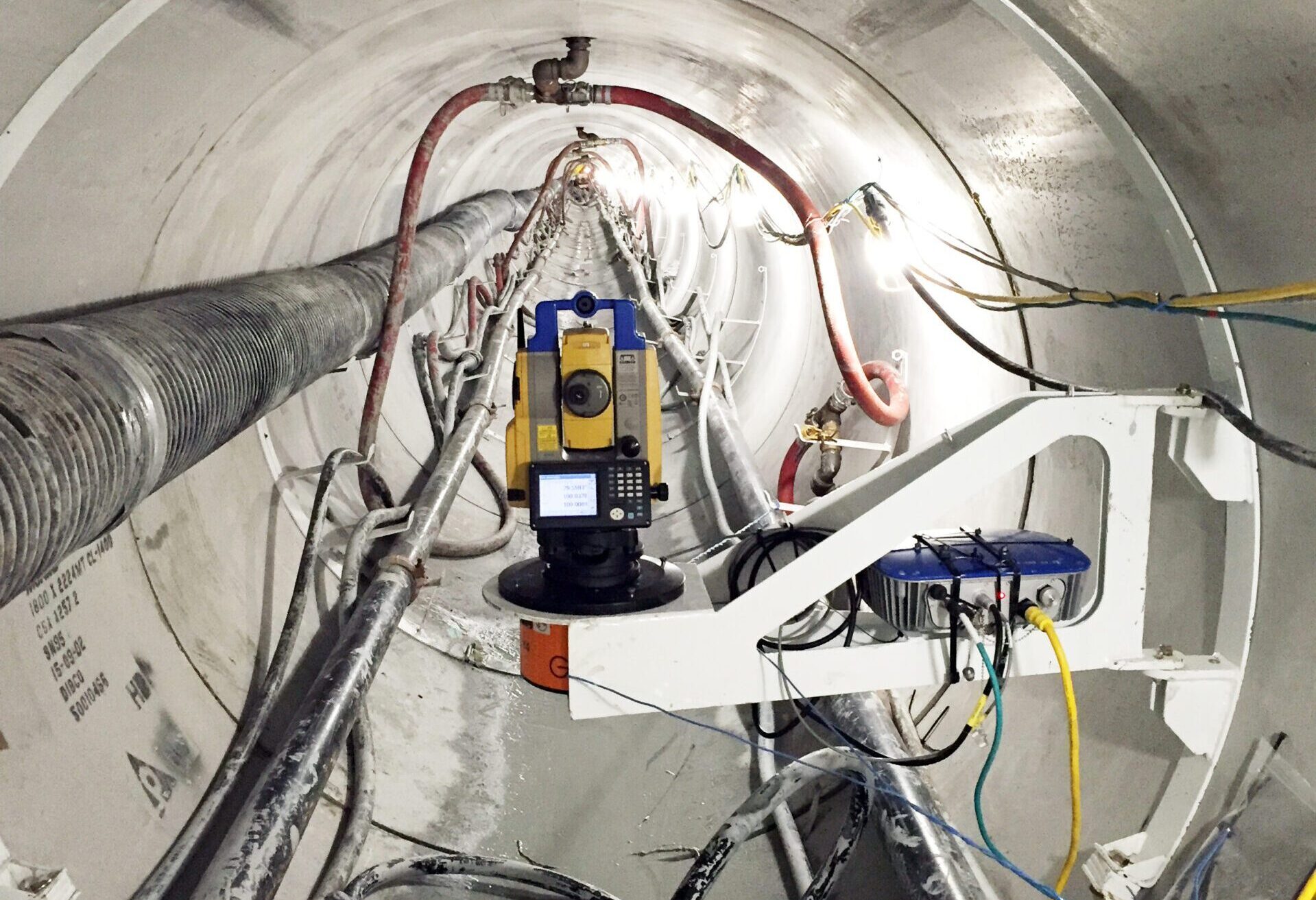

Developed by Akkerman to support long-distance and curved pipe jacking, the AZ100 TGS is a self-surveying azimuth-based total guidance system. The AZ100 TGS minimizes errors often encountered with other types of guidance systems due to laser deflection or MTBM drift. Using fixed reference prisms or “azimuths” strategically located on the launch shaft, a “shaft station” communicates with self-leveling total stations via prisms inside the tunnel. Positioned at a fixed distance from the MTBM to eliminate refraction from atmospherics, an MTBM “pipe station” projects a laser onto the MTBM target allowing the operator navigation control. During this operation, the series of total stations communicate at regular intervals while referencing their position to the azimuths each time. This ensures line and grade accuracy at extremely long distances or complex alignments.

Features:

- An initial survey to ascertain tunnel starting and endpoints is the only survey that is required. This reduces downtime.

- Each total station can be separated by 1,000-3,500-linear feet depending on prism size, tunnel diameter, and atmospherics.

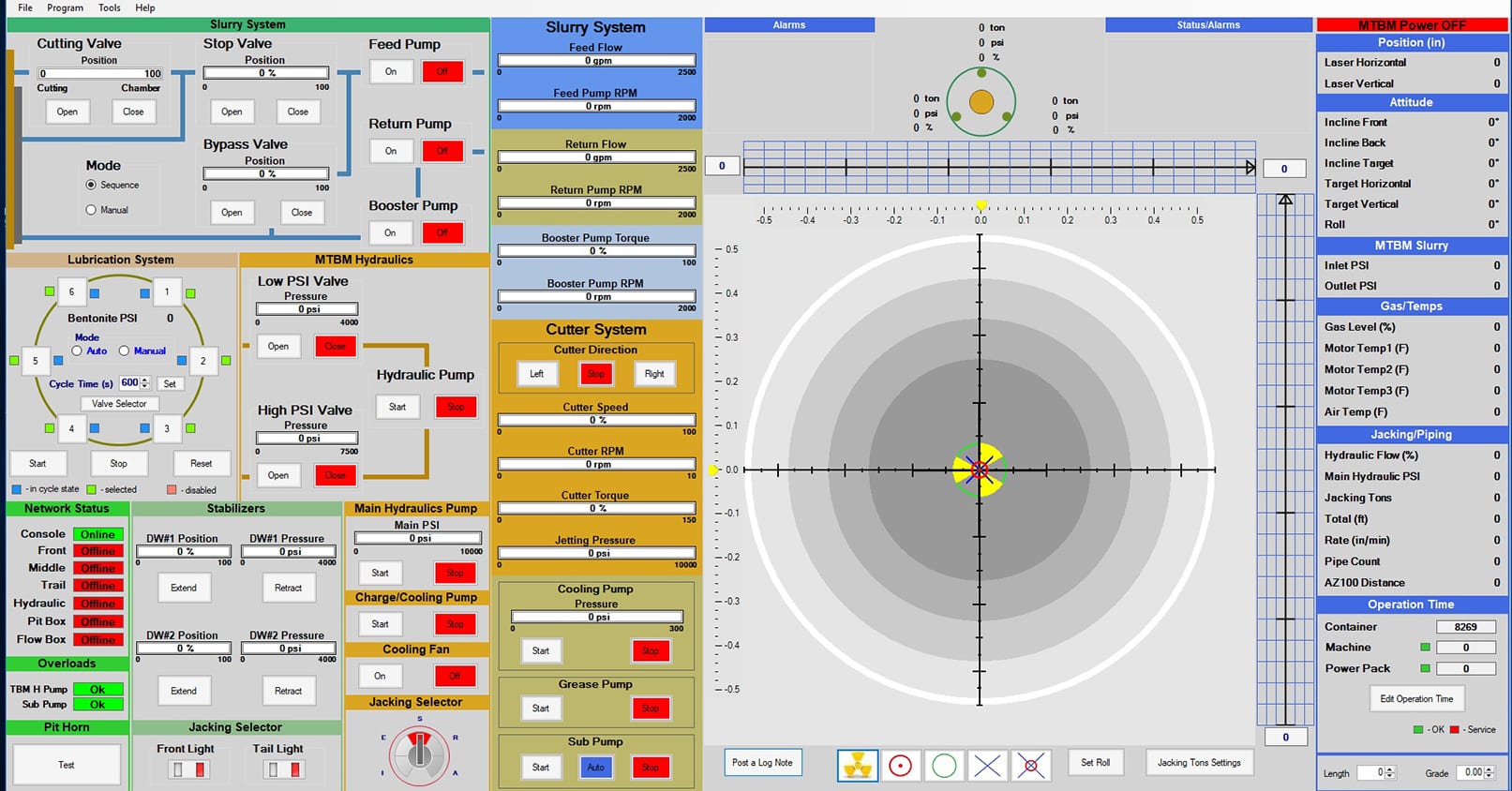

- The AZ100 TGS data logs over 100 data points for customized reporting to track and graph alignment deviation, face pressure, and torque changes.

- Guidance system automatically self-surveys during pipe installation. The MTBM operator can manually request a survey check with a push of a button.

- AZ100 TGS guidance system software is supported on Akkerman microtunneling control systems.

- Requires DTA programming. Offered by Akkerman.

AZ100 Total Guidance System (TGS)

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.