To convert primary pipe jacking equipment to readily install several types of two‐pass lining systems, Akkerman offers customers customized Propulsion Cans and Erectors for the specific liner.

Propulsion Cans consist of a series of hydraulic thrust cylinders arranged inside a trailing shield or can. When activated by the TBM operator, the cylinders advance the TBM, transmitting forces onto the previously constructed tunnel liner set. When operating in this manner, the thrust loads necessary to move the TBM are more consistent and limited to the face pressure to excavate the soil at the cutter head. The skin friction on the TBM in front of the Propulsion Can is not adversely affected by the tunnel’s overall length.

Generally, larger diameter project installations require the insertion of additional product pipe inside the tunnel. Propulsion cans are also used on these projects directly behind the pipe jacking equipment for longer distances and smooth advancement control.

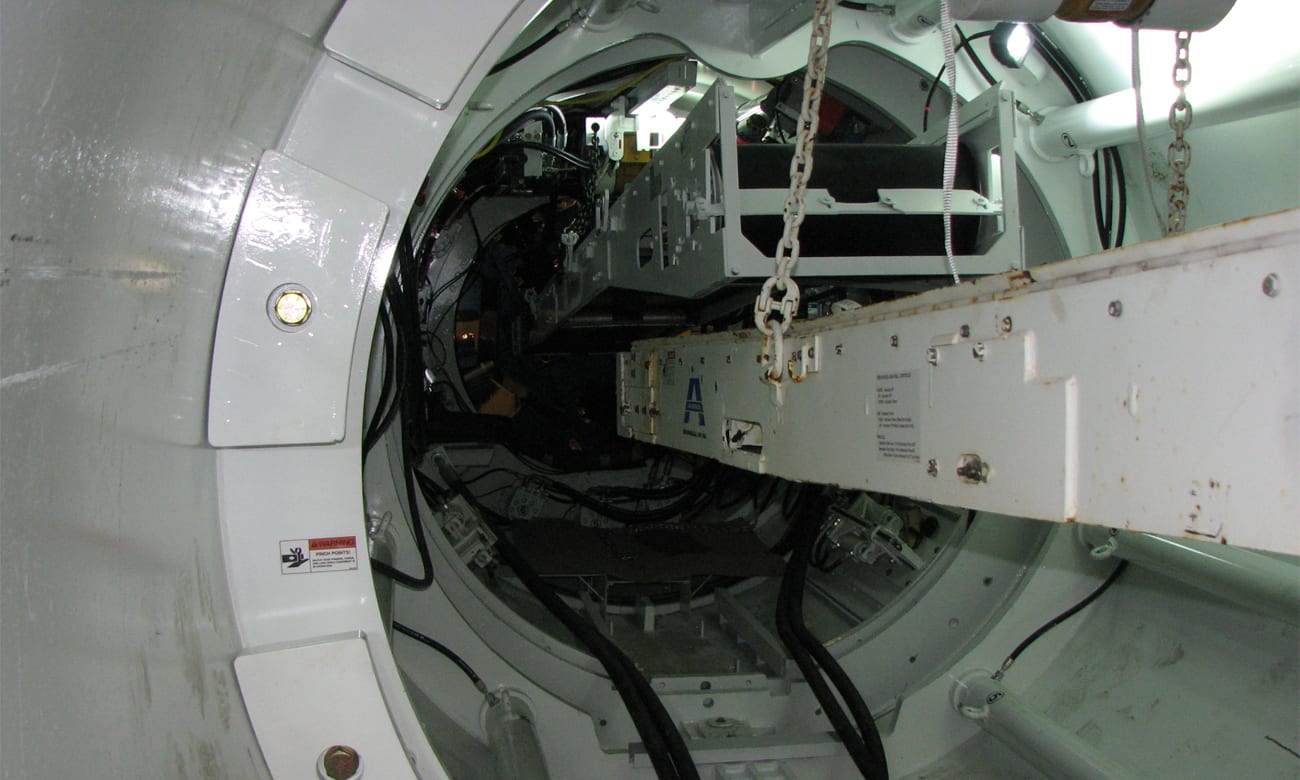

An Erector is a mechanical device that assists with the construction of a two‐pass liner system. Due to space constraints, these systems are typically used in larger diameter tunnel boring machines (TBM), earth pressure balance machines (EPB), or shield tunneling to expedite construction and ease the manual labor from tunnel workers. Note that since the microtunneling method does not permit manned entry during tunneling operations, Erectors are not used on these projects.

Erectors are custom designed and manufactured with our in‐house engineering and manufacturing team to match the tunnel liner installed.

Propulsion Cans & Erectors

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.