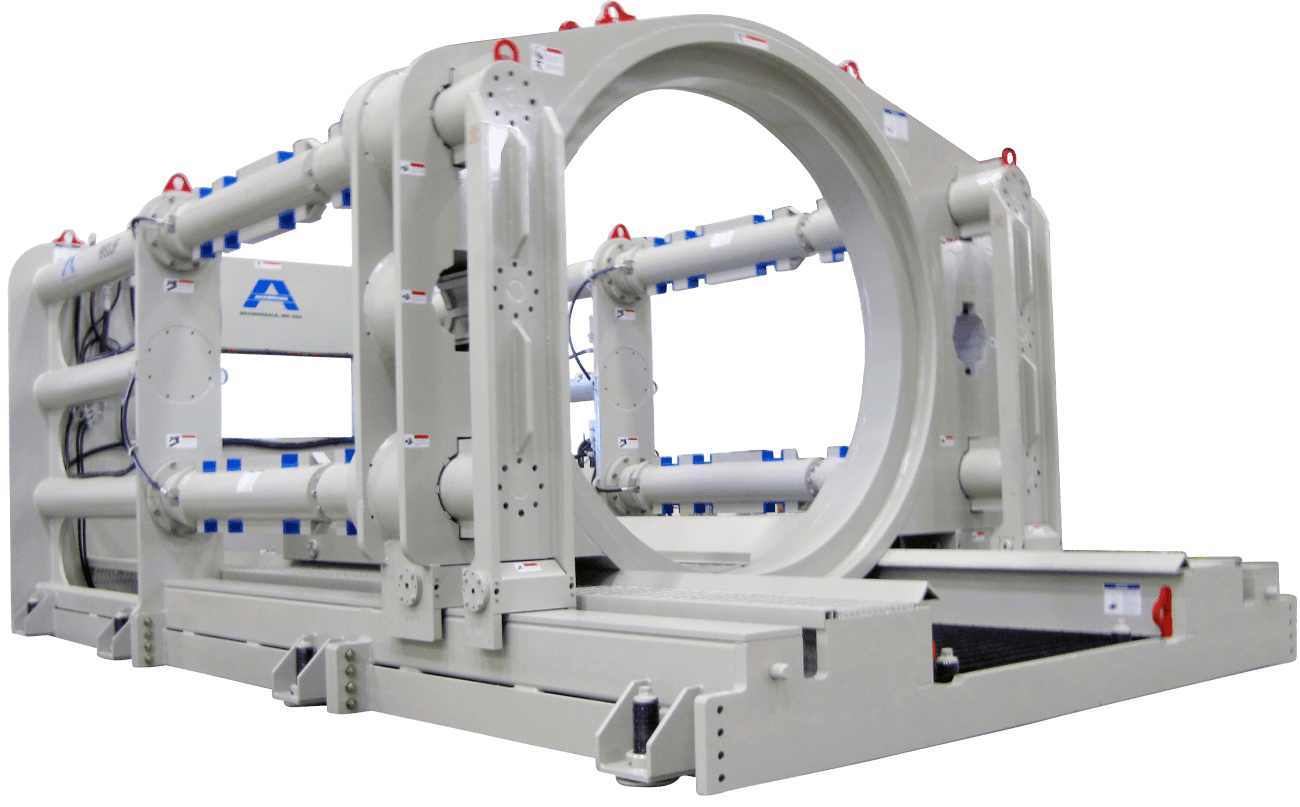

The Pipe Jacking Keyhole Jacking Frame includes horizontally mounted hydraulic cylinders with keyed notches that lock into place and ensure smooth and continuous TBM and pipe advancement. The frame’s hydraulic functions include extend, retract, high flow return, and auxiliary control.

The Pipe Jacking Keyhole Jacking Frame is positioned in front of a reaction wall on the design axis. A stationary set of cables is routed from the power pack to the jacking frame in the launch shaft. The Pipe Jacking Keyhole Jacking Frame exerts continuous and uniform hydraulic jacking force onto a thrust ring, which moves the TBM and pipe along the alignment path. The jacking frame force reacts against the concrete thrust block and the ground outside of the shaft.

Akkerman standard Pipe Jacking Keyhole Jacking Frame sizes selected by size to accommodate the TBM, pipe diameter, dirt bucket, and shaft lengths can be customized to suit project needs.

Features:

- Pipe Jacking Keyhole Jacking Frame Family complement All Akkerman TBM models

- Keyed notches on the cylinders lock into place to ensure smooth and continuous advancement

- Exerts continuous and uniform hydraulic jacking force onto a thrust ring

- Guidance system notch in the thrust plate to allow for pipe laser projection down the tunnel centerline

- Some models are configurable for additional thrust cylinder capacity with the addition of a thrust cylinder kit

MT460K-PJ

MT860K-PJ

MT875K-PJ

MT890K-PJ

MT8102K-PJ

MT8104K-PJ

MT8114K-PJ

Specifications

| Model | Thrust | Pipe OD Max | Weight |

|---|---|---|---|

| MT460K-PJ | 400 ton | 62 in | 35,000 lbs |

| MT860K-PJ | 800 ton | 62 in | 45,000 lbs |

| MT875K-PJ | 800 ton | 77 in | 56,000 lbs |

| MT890K-PJ | 800 ton | 93 in | 60,000 lbs |

| MT8102K-PJ | 1200 ton | 104 in | 74,000 lbs |

| MT8104K-PJ | 1200 ton | 106 in | 75,000 lbs |

| MT8114K-PJ | 1200 ton | 116 in | 85,000 lbs |

- Weights dependent on configuration of final unit.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.