For over two decades, Akkerman has revolutionized the pilot tube guidance system technology. Current capabilities have far surpassed industry expectations just a few short years ago with innovative procedures and technology that have allowed installations exceeding 600-lf with pinpoint accuracy.

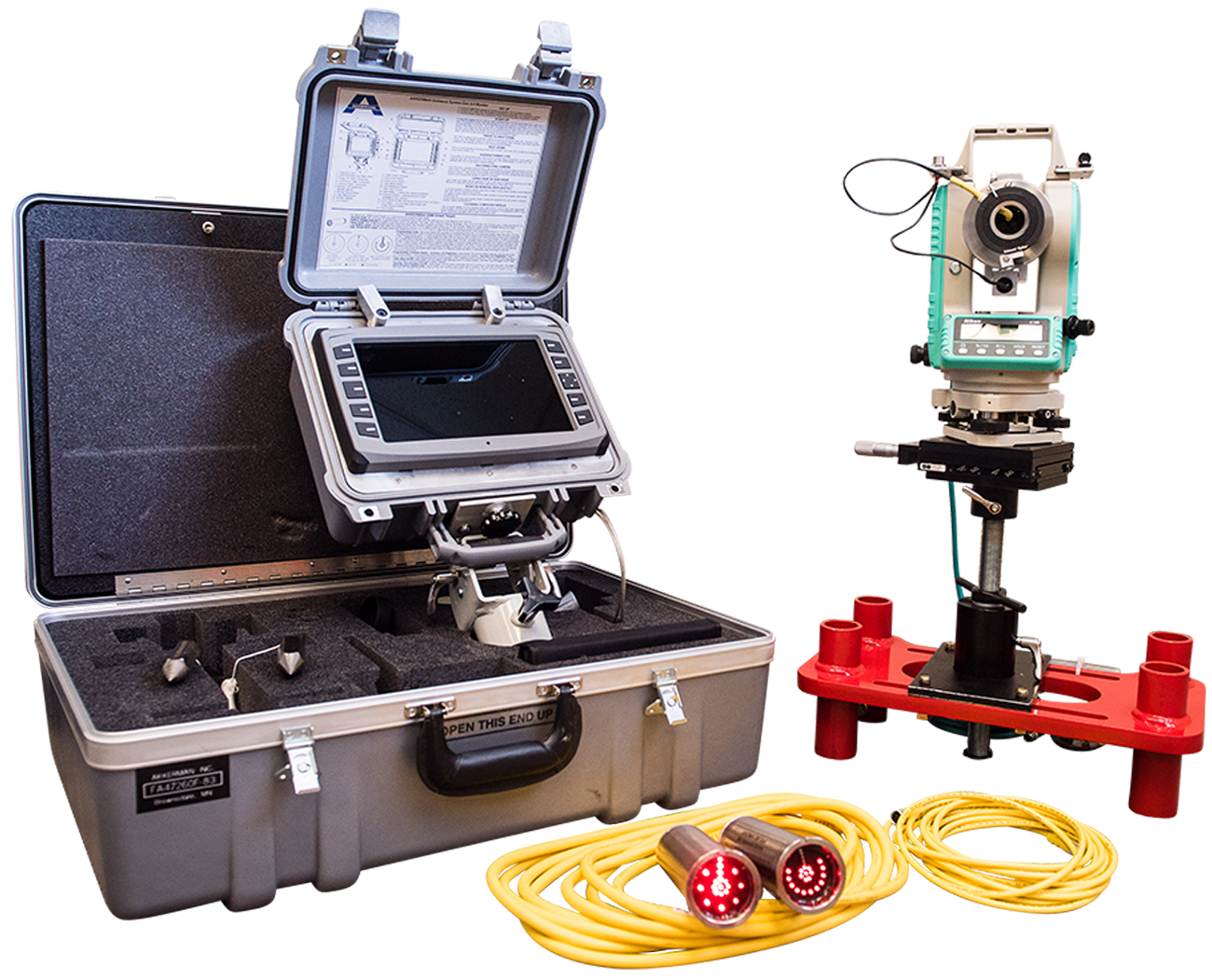

Using a theodolite with advanced remote-controlled optics set to the desired line and grade, the GBM operator visually tracks the position of the steering head of the pilot tube in real-time. The rugged monitor and controls are purpose-built specifically for pilot tube installation to avoid any contact with the theodolite once set-up.

For contractors that require electronic data logging throughout the alignment, an optional data logging package can be installed on your GBM system to record navigation metrics as well as machine parameters along the alignment.

Features:

- Optional: Pilot Tube data logging technology. Capture parameters of installation every 5s.

- Optional: Smart Target Technology allows the GBM operator to change display settings of the LED target, set sleep mode to preserve battery life during shut-down periods, and indicates high temp warning without pulling back pilot tubes for adjustment.

- Standard LED targets use replaceable batteries with estimated battery life measured in weeks.

- Akkerman GBM guidance systems can be customized to fit on other pilot tube manufacturer’s equipment.

- Guidance systems are adaptable and can be used on any Akkerman GBM system.

GBM Guidance System

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.