Guided auger boring is one of the most popular trenchless methods for accurate installation of steel casings in North America. Akkerman offers several tools contractors can select to adapt their pilot tubes to steel casing based on the projects’ ground conditions.

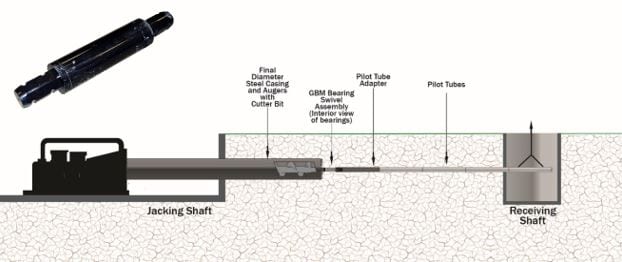

GBM Bearing Swivel

Once the pilot tubes are installed on line and grade, the GBM bearing swivel assembly is installed between the last pilot tube and the cutterhead driven by the rotating auger string.

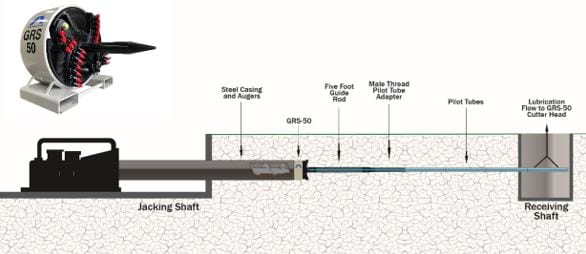

GRS Cutterhead

The pilot tube Guide Rod Swivel (GRS) cutterhead welds onto the lead casing and contains an internal swivel bearing located behind the cutting face. The bearing assembly is interchangeable between multiple casing diameters and keeps the casing on line and grade achieved from the installed pilot tubes. The needle connection between the GRS cutterhead and pilot tubes allows for fluid delivery from the reception shaft to assist difficult bores, while retractable cutters allow tripping of augers if an obstacle is encountered.

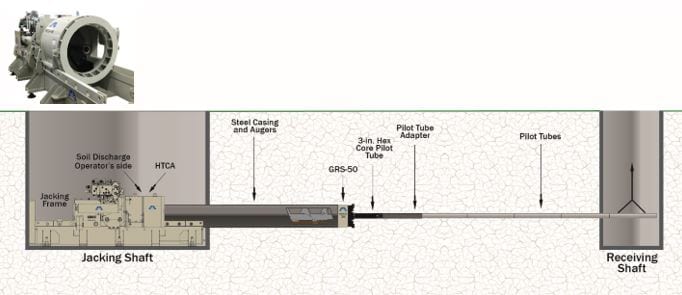

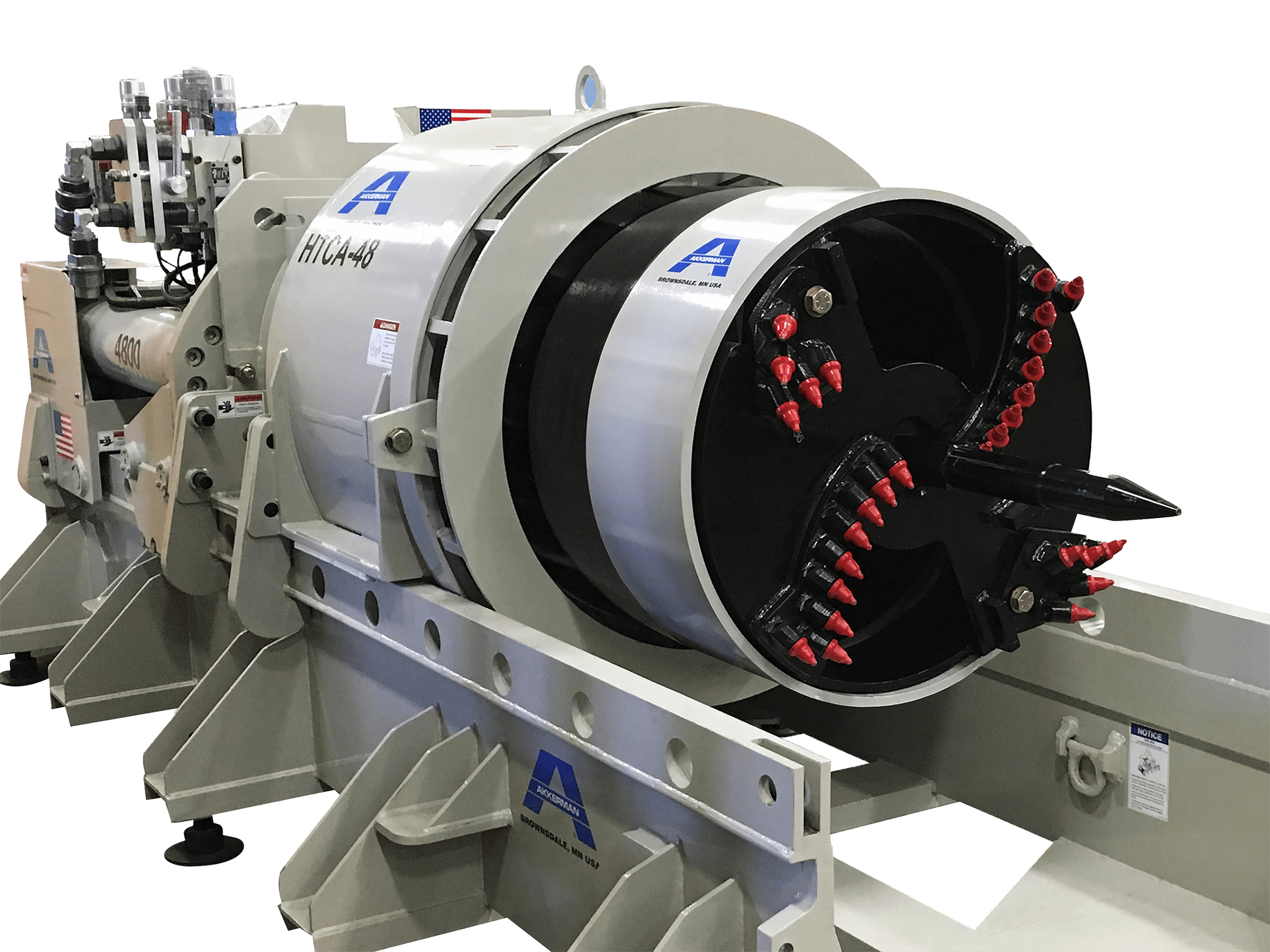

High Torque Casing Adapter (HTCA)

The HTCA attachment turns the already versatile 4800 series GBM system into an 88,000 ft-lbf monster machine able to perform all guided auger bore functions. The HTCA simply locks into place directly in front of a 4800A GBM and includes the master ring, dirt paddles, and discharge chute to install steel casing up to 36in. With an HTCA installed on a 4800A, contractors can perform guided auger boring in smaller shafts without dangerous exhaust gases.

Benefits & Features

- GBM Bearing Swivel connects to your existing auger boring cutterhead or lead auger.

- Bearing Swivel and GRS Cutterhead suitable for densely compacted ground and soft rock.

- Interchangeable GRS bearing assembly saves contractors money.

- GRS Cutterheads utilize 6×5 inch hex adapter for ultimate durability and mating versatility.

- GRS Cutterheads feature wing cutters suitable for auger removal.

- HTCA allows 4800A GBM owners to use one piece of equipment to install pilot tubes and auger bore steel casing with one set-up, while minimizing shaft size and reduce the disturbance of a diesel engine running below grade.

GBM Bearing Swivel Assembly

Guided Rod Swivel 50 – Models GRS-24, GRS-26, GRS-28, GRS-30, GRS-36

High Torque Casing Adapter (HTCA)

Augering Adapter Assembly

Specifications

| Model | Rating | Diameter | Weight |

|---|---|---|---|

| Bearing Swivel | 50 ton | Up to 24 in | 100-lbs. |

Guide Rod Swivels

| Model | Rating | Diameter | Weight |

|---|---|---|---|

| GRS-24 | 50 ton | 24 in | 1,200-lbs. |

| GRS-26 | 50 ton | 26 in | 1,300-lbs. |

| GRS-28 | 50 ton | 28 in | 1,400-lbs. |

| GRS-30 | 50 ton | 30 in | 1,500-lbs. |

| GRS-36 | 50 ton | 36 in | 1,800-lbs. |

High Torque Casing Adapter

| Model | Torque (lo/hi) | Speed (hi / lo) | Weight |

|---|---|---|---|

| HTCA-4800 | 40,000 ft-lbf / 88,000 ft-lbf | 16 rpm / 10 rpm | 4,800-lbs. |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.