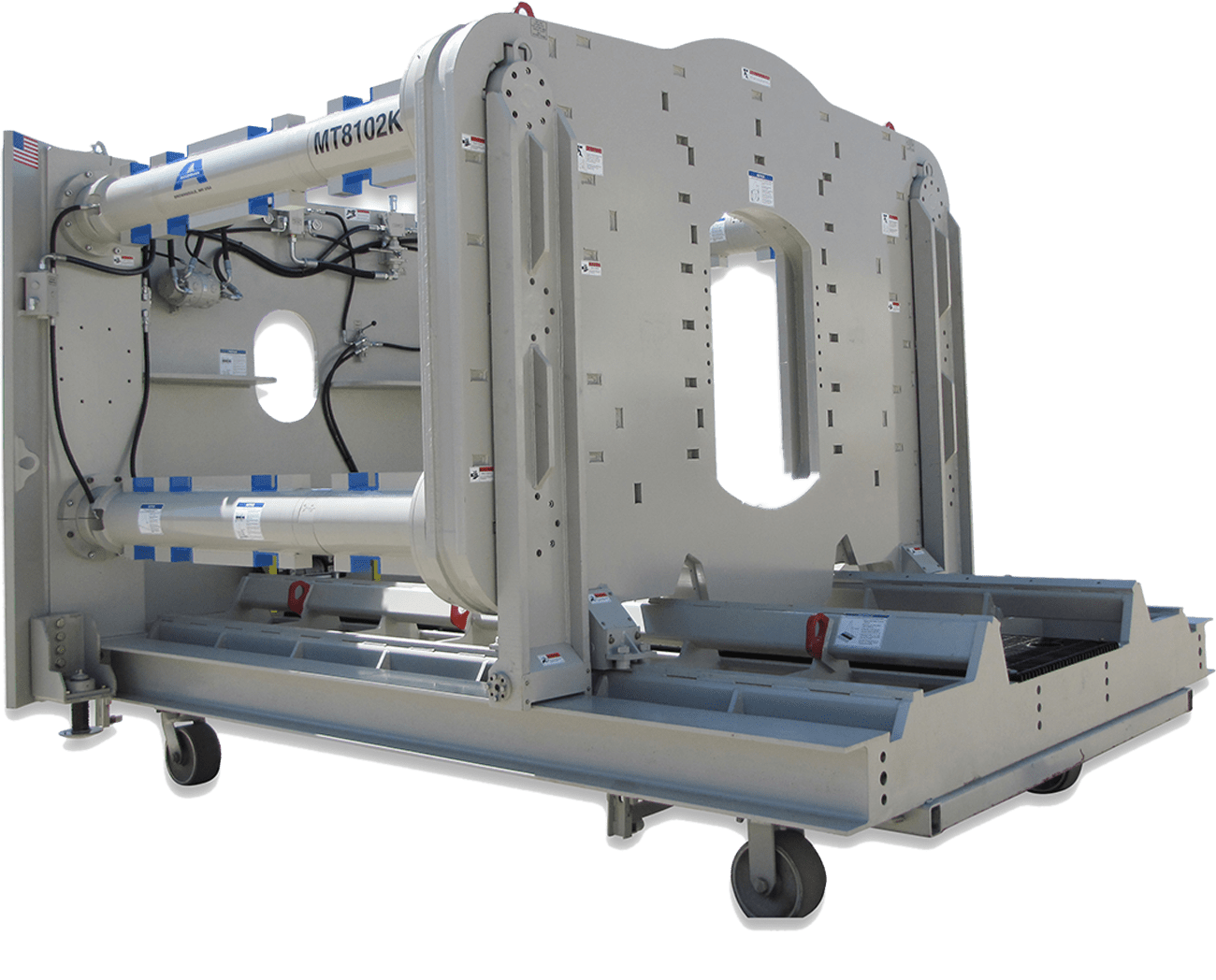

Akkerman MTBM jacking frames are built to deliver high thrust capacity while minimizing launch shaft requirements. The multi-cylinders keyhole design applies thrust loads through the center of the pipe axis minimizing stress concentration on pipe joints. MTBM jacking frames are remotely controlled from the surface or can be pendent controlled from a power pack and used for other pipejacking methods with a service bay attachment.

Features

- Keyed thrust cylinders are interchangeable between each unit reducing cost.

- Additional thrust cylinders can be added on MT8102K and larger jacking frames to increase thrust capacity for extended drives.

- Curved or Flat reaction walls are optional.

- Hydraulic plumbing is efficiently routed and provided synchronized operation of cylinders.

- Auxiliary hydraulics allow quick pullback of thrust block or operation and portal seal pipe break.

- Hi-Flow return valve allows quick cycle times between thrusting.

- Reaction wall designed for tunnel guidance system placement and tool storage.

- Standard pipe length is 10-ft. Extension kits available up to 20-ft pipe sets.

- Service bays available for TBM projects.

- Frame designed for in-shaft assembly to reduce crane size requirement.

- Minimum Shaft Size: Varies on configuration. 16-ft to 24-ft

MT460K

MT860K

MT875K

MT890K

MT8102K

MT8108K

MT8114K

Specifications

| Model | Thrust | Pipe OD | Est. Weight |

|---|---|---|---|

| MT 460K | 400 ton | 30-60 in. | 27,000 lbs. |

| MT860K | 800 ton | 30-60 in. | 30,000 lbs. |

| MT875K | 800 ton | 60-75 in. | 40,000 lbs. |

| MT890K | 800 ton | 75-90 in. | 43,500 lbs. |

| MT8102K | 1200 ton | 90-102 in. | 58,000 lbs. |

| MT8108K | 1200 ton | 90-108 in. | 72,500 lbs. |

| MT8114K | 1200 ton | 102-114 in. | 75,000 lbs. |

- Weights dependent on configuration of final unit.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.