Tunnel lubrication plays a pivotal role in the success of all trenchless methods while improving the performance of tunneling, pipe jacking, microtunneling, guided boring, and horizontal directional drilling systems. The right lubrication system not only reduces frictional forces along the pipe string, but today’s advanced systems also incorporate variable flows, pressures, and additional pumping strategies that enhance material flow and maximize the mechanical properties of the trenchless equipment design.

A common misconception in the trenchless industry is that the lubricant, often referred to as bentonite slurry, coats the jacking pipe and makes it slippery. While a well‐designed mixture will seem to have these results, lubrication mixtures are formulated based on the site’s geology, trenchless equipment design, and lubrication system capacity to maintain the open annulus created between the cutter head and the jacking pipe. In certain ground conditions, the use of an improper mixture or misapplication can lead to increased jacking loads or even failure.

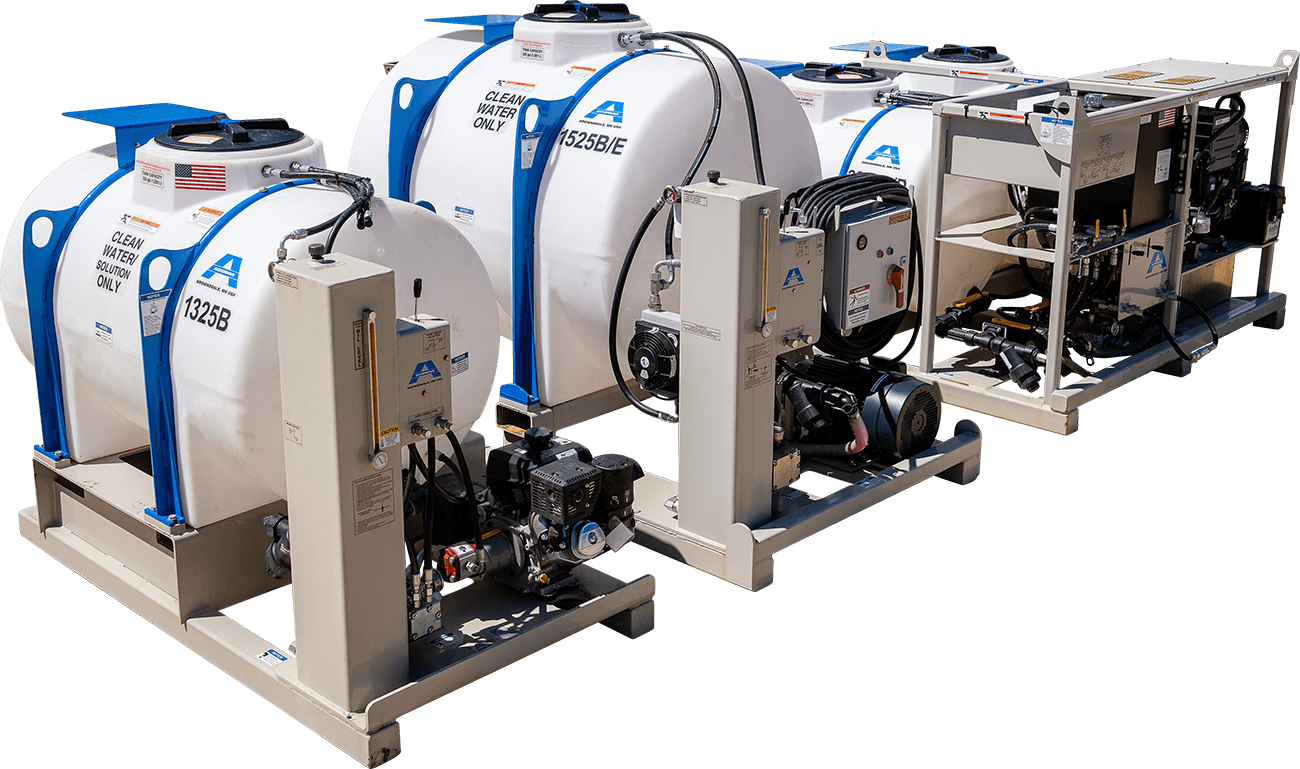

High Pressure Lubrication Systems

Below is a general guideline, given as a starting point for your next project. We always recommend consulting with a mud engineer for an on‐site evaluation of your geology.

| Ground Type | Ground Conditions | Reactivity | Lubrication Mix |

|---|---|---|---|

| Coarse Soils | Sands, Gravel, Rock | Non-Reactive. Does not swell. Does not get sticky. | Water (pH-controlled), Bentonite. Addition of PAC or Xantham Gum may be required |

| Fine Soils | Clay & Shale | Reactive. Tendency to swell with water. Can get sticky. | Water (pH-controlled), Bentonite with clay inhibitor. Surfactant to reduce stickiness |

| Mixed Soils | Variable | Ground may react differently depending on the ratio of coarse/fine material | Mixture of Bentonite, Flocculant, or clay Inhibitor |

Akkerman produces a complete family of lubrication/mud pumps suited for the trenchless industry’s rigorous demands. High‐pressure lubrication pumps are the perfect complement to extend distances during pilot tube installations. These same systems are versatile and mobile for any trenchless project, like pipe jacking, microtunneling, auger boring, directional drilling, and vertical drilling applications, to name a few.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.