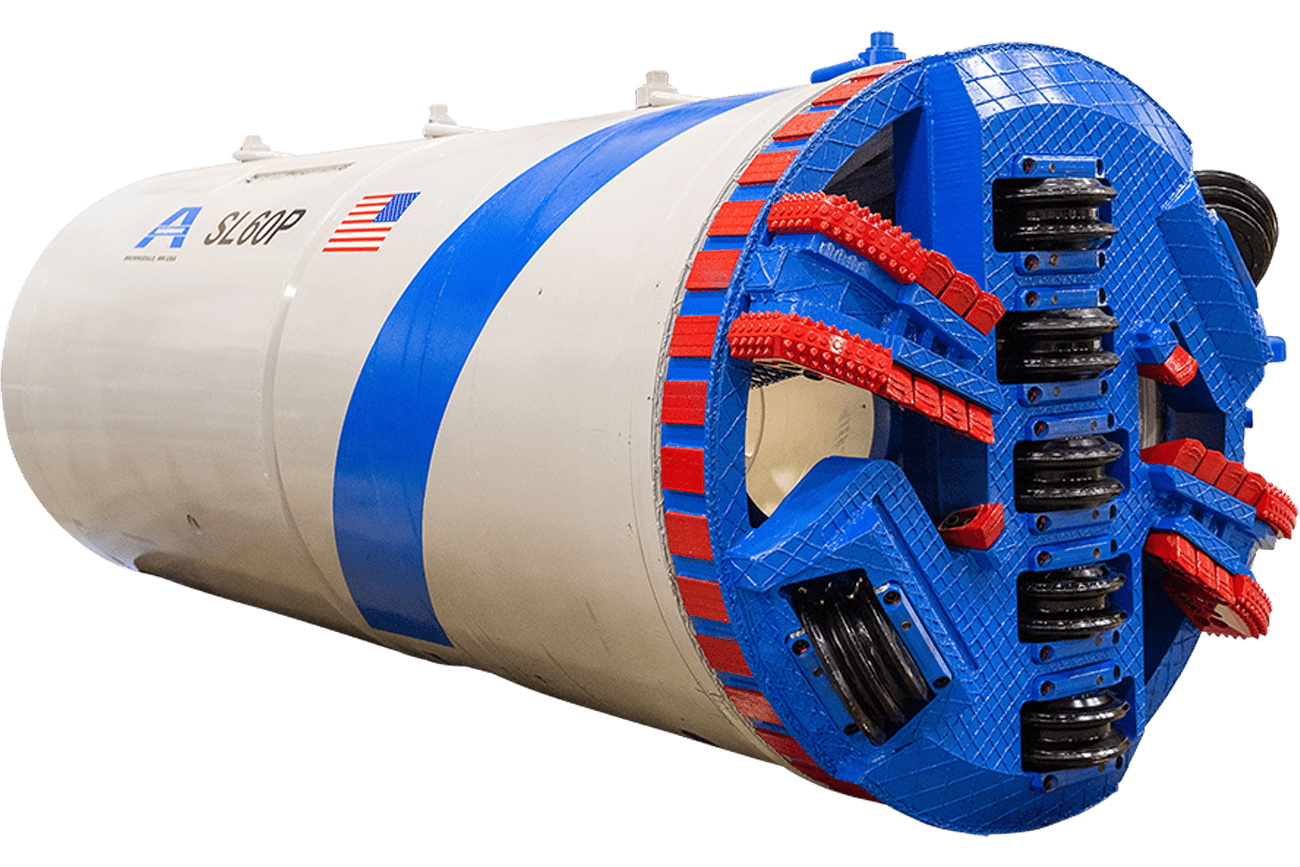

Akkerman periphery drive slurry microtunneling systems (SLP) are designed to deliver powerful performance for extended distances and curved alignments. These units include an on-board power pack with remotely selectable torque ranges to conquer changing ground conditions. Like all Akkerman microtunneling systems, the SLP lineup is fully remote-controlled from the surface and offers face access for cutterhead inspection, tool replacement, or obstruction removal.

Features:

- All SLP series microtunneling systems use the same Akkerman Microtunnel Control Container (MCC) as SLC models with the addition of a remotely controlled periphery drive power booster container.

- Airlock kits available for pipe diameters of 78in ID and larger per PVHO and OSHA standards.

- Sizing kits available to accommodate multiple diameters with one MTBM.

- Interchangeable cutterhead types: Soft Ground, Mixed Face, Rock

- Selectable high pressure jetting nozzles to assist ground flow and cutting in cohesive soils.

- Variable flow slurry routing to control hydrostatic balance to cutting head or plenum chamber based on encounter ground conditions.

- Sealing system to 3 bar capacity. Underwater retrieval compatible with sealed adapters.

- Mechanical and hydrostatic balancing with remote monitoring.

- Active MTBM monitoring and report generation including gas detection, roll, slurry monitoring, steering position, guidance, electrical connectivity, and more.

- All SLP systems compatible with Akkerman TGS guidance system.

MTBM SL60P

MTBM SL74P

MTBM SL82P

MTBM SL86P

MTBM SL96P

MTBM SL114P

Specifications

| Model | Power / Torque | Diameter / Cut Dia. | Est. Weight |

|---|---|---|---|

| SL60P | 250 hp / 185,000 ft-lbf | 60 in / 62 in | 32,000 lbs |

| SL74P | 400 hp / 300,000 ft-lbf | 74 in / 76 in | 40,000 lbs |

| SL82P | 400 hp / 350,000 ft-lbf | 82 in / 84 in | 48,000 lbs |

| SL86P | 400 hp / 404,000 ft-lbf | 86 in / 88 in | 53,000 lbs. |

| SL96P | 500 hp / 500,000 ft-lbf | 96 in / 98 in | 60,000 lbs |

| SL114P | 500 hp / 600,000 ft-lbf | 114 in / 116 in | 80,000 lbs |

- Weights dependent on configuration of final unit.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.