When it comes to mud/fluid mixing, what matters most is aggressive agitation, a homogeneous blend, capacity, and powerful pump flow.

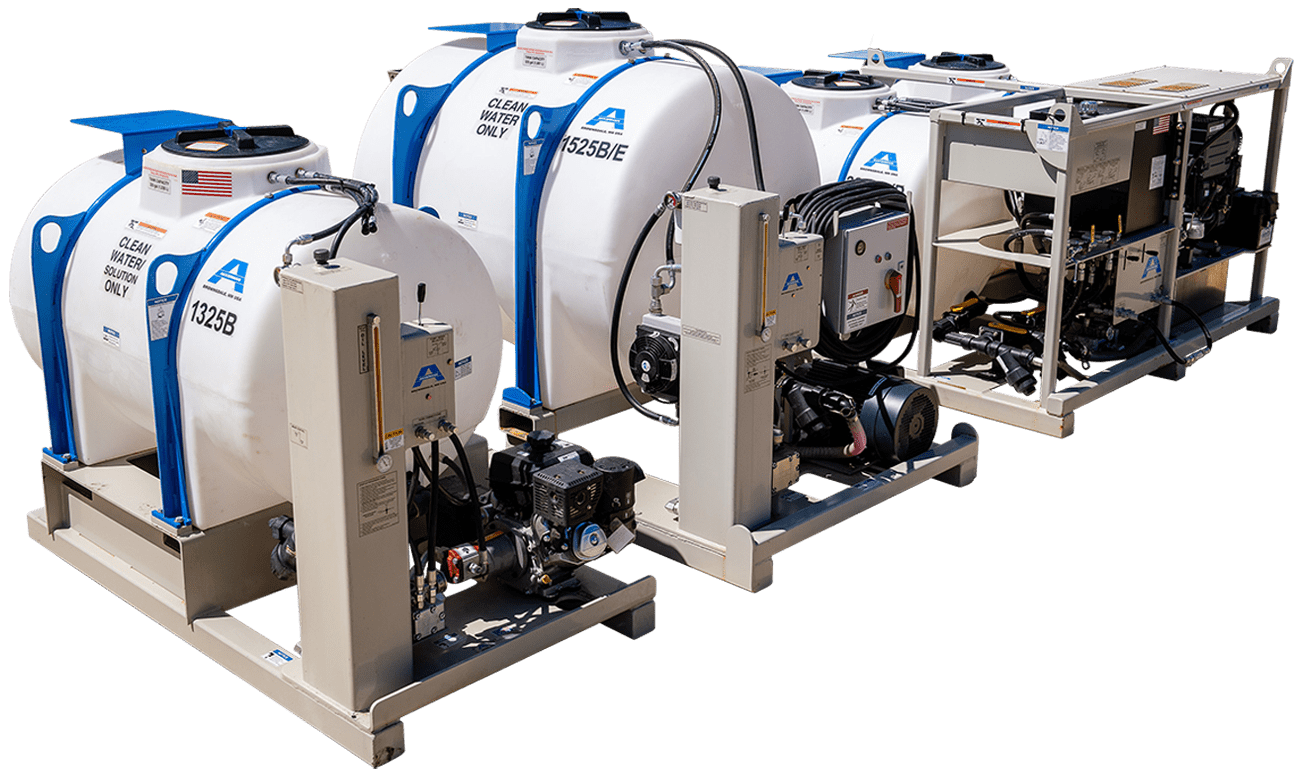

Our Bentonite and Lubrication systems are designed to fully hydrate your mixtures in less time with the pumping capacities required to enhance distances. They’re used on various projects, including guided boring, microtunneling, tunneling operations, conventional auger boring, HDD, and any application involving high viscosity heavy fluid mixing.

Safety and reliability are at the forefront with each design with features like a shrouded agitator, no belts, step‐up access to the tank, a mud supply platform, an in‐line suction strainer, and tank. A simple control panel and an in‐shaft control pendant complete the package.

Features:

- Pump water or water with mud for fluid mixing

- Aggressive in‐tank agitator maintains a homogeneous mixture by continuous mixing, independent agitation or agitate and pump

- Hydraulically‐driven, high pressure with relief valve

- Pressure is adjusted to match tooling requirements

- In‐shaft control pendant comes standard with each assembly and allows operators to vary flow and pressure as needed

- Sized to provide enough supply for the duration of the shift

- Easy connection to mud/fluid supply

1325B/G

1525B/E

1525B/D

2325B/E

2325B/D

Specifications

| Model | HP | Pump | Capacity / Weight |

|---|---|---|---|

| 2325B/D | 30hp Diesel Tier IV | 6 & 10 gpm 2,500 psi | (2) – 325 gal. / 3,150 lbs. |

| 2325B/E | 30hp Electric 480VAC | 6 & 10 gpm 2,500 psi | (2) – 325 gal. / 3,150 lbs. |

| 1525B/D | 20hp Diesel Tier IV | 10 gpm 2,500 psi | 525 gal. / 2,200 lbs. |

| 1525B/E | 20hp Electric 480VAC | 10 gpm 2,500 psi | 525 gal. / 2,200 lbs. |

| 1325B/G | 14hp Gas | 6 gpm 2,500 psi | 325 gal. / 1,000 lbs. |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.