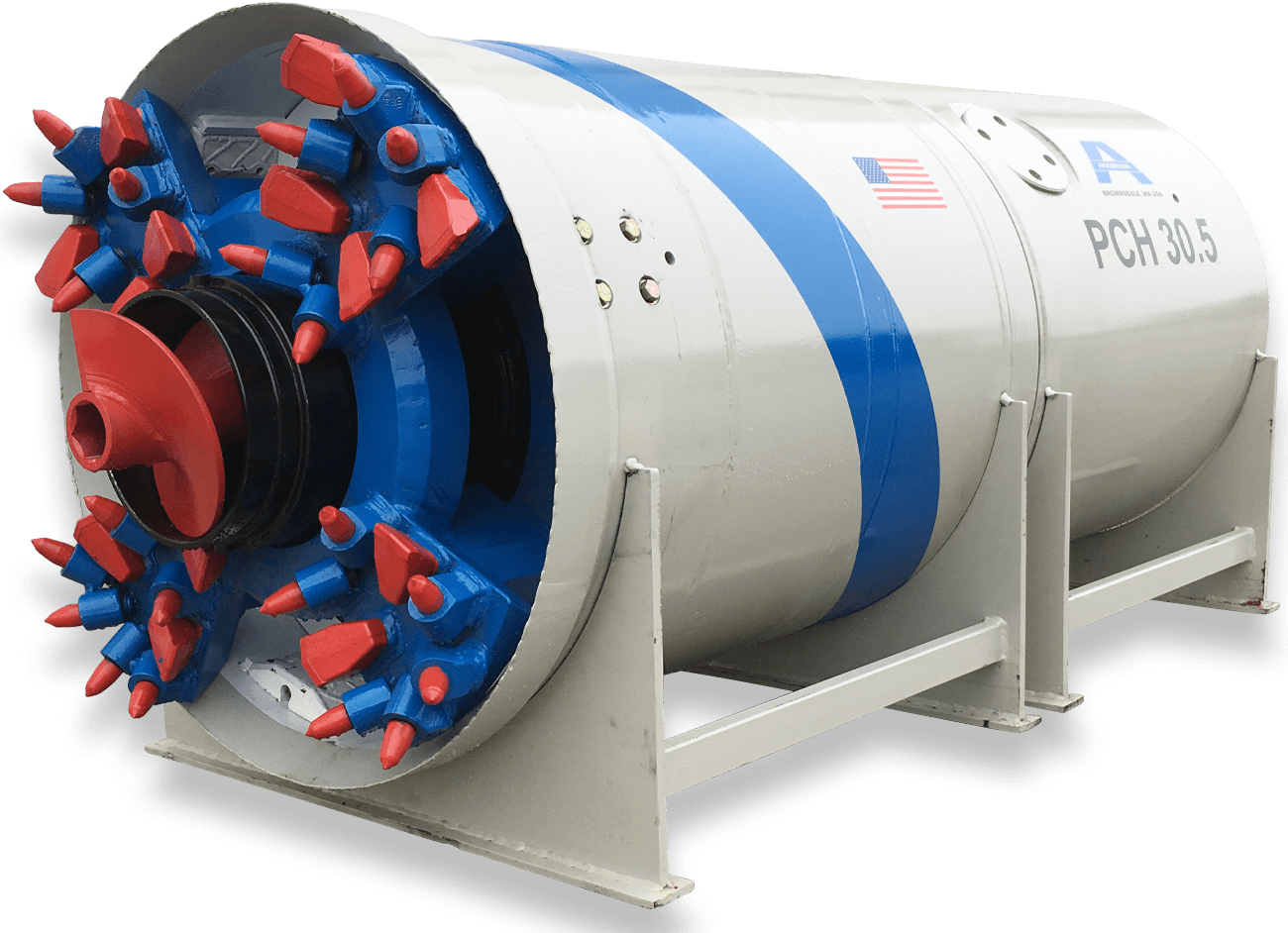

Akkerman’s Powered Cutting Heads (PCH) and Powered Reaming Heads (PRH) set the standard for pilot tube microtunneling. These powerful units increase the diameter of the bore to match the final product pipe while reversing the direction of the material discharge of the excavated material to the reception shaft in order to install any standard allowable jacking pipe suitable for the application.

Powered Cutting Heads (PCH) Features:

- PCHs feature independent hydraulic drive systems that allow the GBM operator to independently control the speed and direction of both the cutterhead and augers.

- High-Pressure Jetting nozzles are controlled by the operator to assist material transfer and cutting in cohesive ground conditions.

- Pipe lubrication ports are plumbed into tail section to promote a stable borehole and reduced pressures.

- Material discharged and reversed inside the plenum chamber creating a mechanical earth balance during excavation.

- Increase kits are available to adapt to various jacking pipe diameters or types.

Powered Reaming Heads (PRH) Features:

- PRH uses a powerful single hydraulic drive system to turn the cutterhead and auger string simultaneously. The drive system is bi-directional.

- The augers and casings are connected to the PRH by reaming arms which promote an open transfer of excavated material to the augers.

- Material discharge is reversed inside the plenum chamber sending excavated material to the reception shaft for removal.

- High-Pressure Jetting nozzles are controlled by the operator to assist material transfer and cutting in cohesive ground conditions.

- Pipe lubrication ports are plumbed into tail section to promote a stable borehole and reduced pressures.

- PRH heads utilize a common drive and gearbox setup. The shield body can be built to match various jacking pipe diameters or types.

PCH 20

PCH 22.5

PCH 30.5

PCH 36

PCH 44

PRH Series II 10.5K Drive

PRH Series II 20K Drive

PRH Series II 26K Drive

Specifications

| Model | Base Diameter | CH HP / Auger Torque | Weight (Drive) |

|---|---|---|---|

| PCH 20 | 20 in. | 32 hp / 10,500 ft-lbf | 1,800 lbs |

| PCH 22.5 | 22.5 in. | 48 hp / 10,500 ft-lbf | 2,000 lbs |

| PCH 30.5 | 30.5 in. | 61 hp / 10,500 ft-lbf | 2,200 lbs |

| PCH 36 | 36 in. | 79 hp / 26,000 ft-lbf | 4,300 lbs |

| PCH 44 | 44 | 93 hp / 26,000 ft-lbf | 6,500 lbs |

*Skin Kits available on all diameters

Powered Reaming Heads

| Model | Diameter Range | Torque | Speed |

|---|---|---|---|

| PRH 10.5 | 14-20 in. | 10,500 ft-lbf | 40 rpm |

| PRH 20 | 20-30 in. | 20,000 ft-lbf | 38 rpm |

| PRH 26 | 30-48 in. | 26,000 ft-lbf | 26 rpm |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.