Akkerman’s Weld-On Casing Adapters are often imitated, but never duplicated. These adapters are designed to connect pilot tubes that have been installed on line and grade to steel casing that will be installed by either auger boring or pipe ramming. Designed with high grade steels and a specific weld process to match, these adapters can be custom built to suit your specific diameters.

Weld-On Reaming Head (WORH) Features:

- Designed for guided auger boring applications in displaceable ground conditions.

- Diameters up to 36-in can be connected directly to the installed pilot tube string using standard Akkerman supplied connections.

- Multi-Stage WORHs are recommended for diameters larger than 36-in. Typical stage is ½ times the final casing diameter for casings up to 72-in.

- Weld-On Reaming heads may be used with a pneumatic pipe ram in the event obstacles are encountered.

- Weld-On Reaming heads allow the contractor to “lag the cutter” behind the adapter creating a natural plug during unstable ground, or easily remove augers for removal of obstacles.

- Standard steel casing bore diameters are stocked. Custom diameters are available.

Guided Ramming Head Features:

- Designed specifically for guiding steel casing installations using pneumatic pipe hammers.

- Optimized to allow dynamic soil movement along the casing walls while resisting fatigue and eliminating side loading to keep the alignment straight.

- An additional 10-ft hex core rod is recommended when connecting ramming heads directly behind pilot tubes to absorb additional shock loads.

- Standard steel casing bore diameters are stocked. Custom diameters are available.

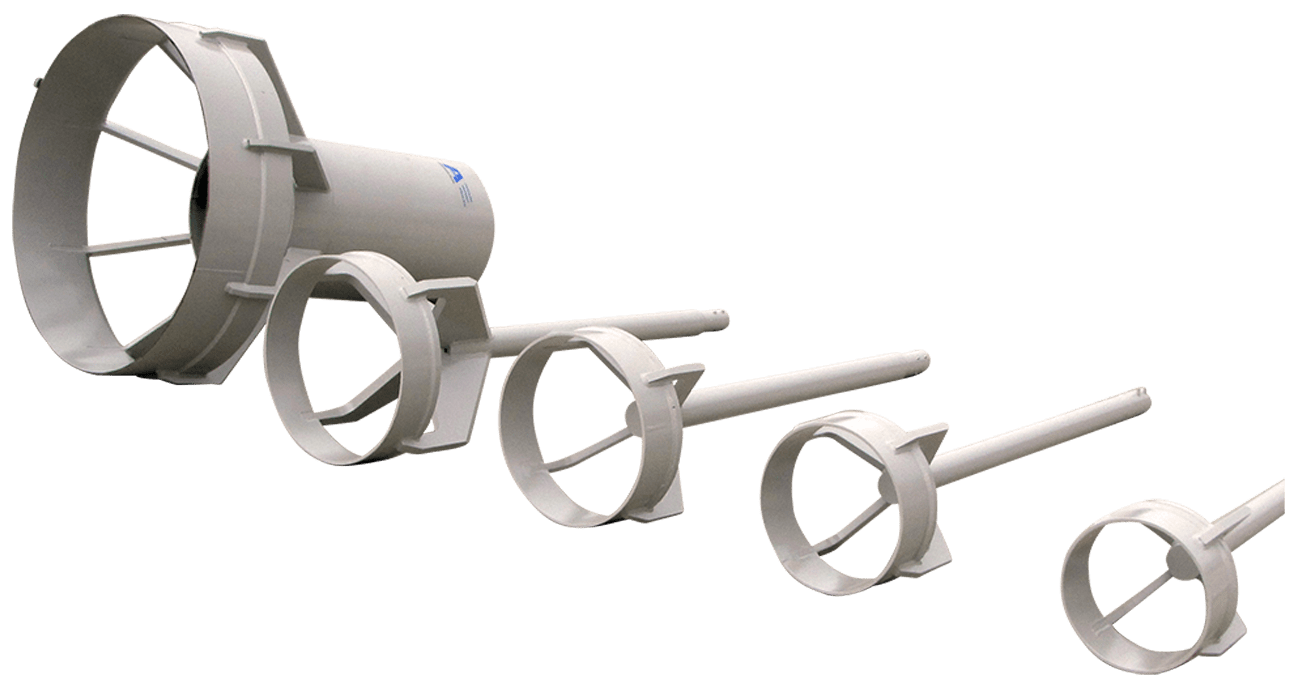

Single‐Stage Weld-On Reaming Head

Two‐Stage Weld‐On Reaming Head

Specifications

Weld-on Casing Adapters

| Model | Diameter | Ground Conditions | Length |

|---|---|---|---|

| WORH Standard | 12‐36 in | N < 30 | 110 in typ. |

| WORH 2-Stage | 42-72 in | N < 30 | 90 in typ. |

| GRH Standard | 20‐36‐in. | Variable | 110 in typ. |

| GRH 2-Stage | Custom | Variable | 90 in typ. |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.