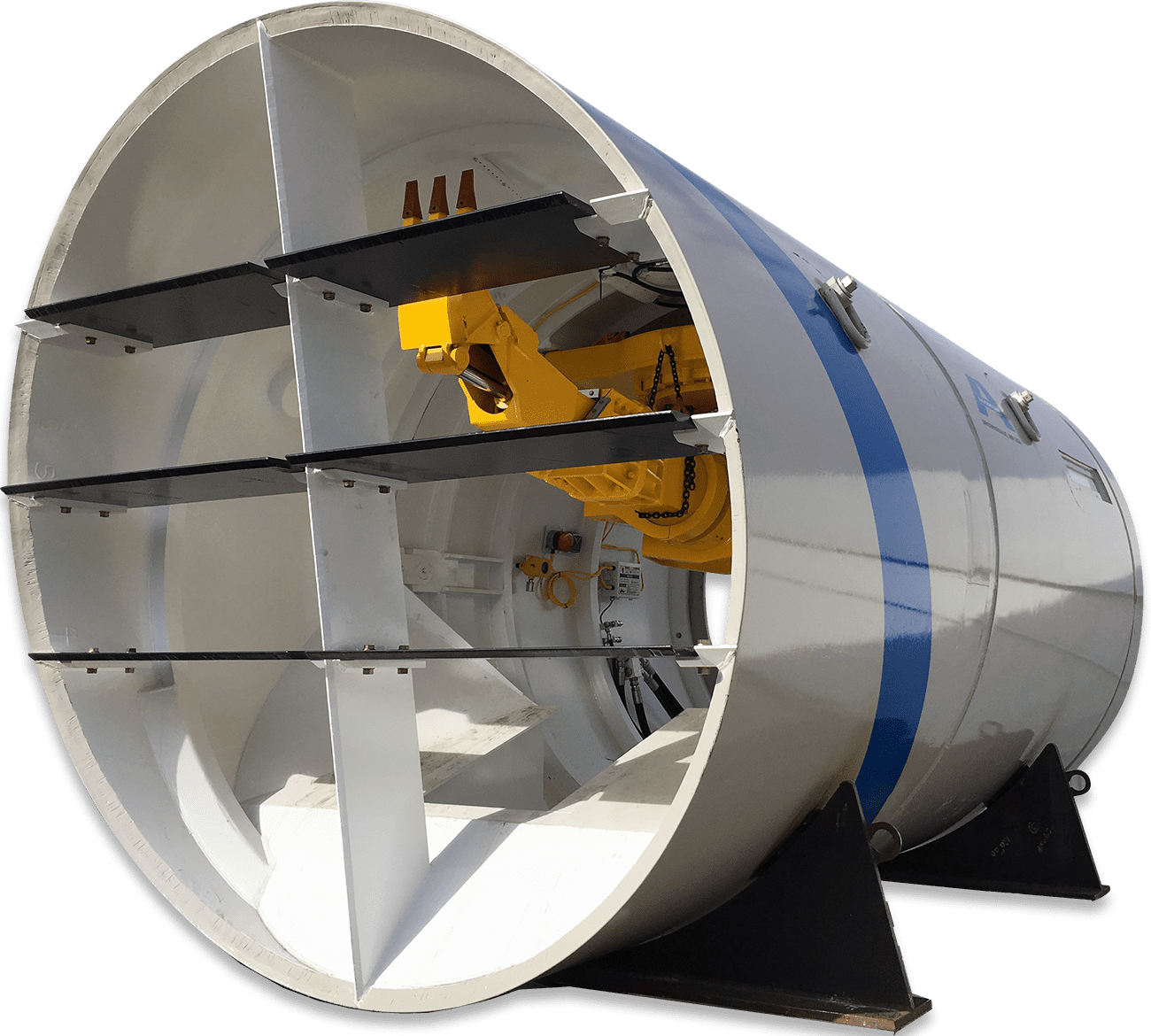

Excavator Boring Shields (EBS) and the EX‐50 Excavator are designed for manned‐entry, open‐face mechanical excavation of large diameter pipe jacking, liner plate, and ring‐beam and lagging tunnel building applications.

The slant faced Excavator Boring Shield and pipe are hydraulically advanced with the Keyhole Jacking/Thrust Frame or with the Tunnel Boring System and 5200 Pump Unit thrust cylinder.

The operator controls the EX‐50 Excavator’s claw with a joy stick and foot controls to excavate spoil for removal onto the belt conveyor to the Haul Unit (Muck Cart) for disposal.

The EX‐50 Excavator’s rotating boom has a full range of motion, including extension beyond the bore’s face to remove obstructions, as necessary.

Tunnel line and grade are controlled with the use of a standard passive pipe laser. The operator assesses the location of a fixed laser point on the EBS cutter head and makes adjustments as necessary.

Sand shelves come standard with every EBSs purchased. They can also be equipped with closeable hydraulic doors to prevent subsidence into the tunnel interior.

Features:

- Simple, cost‐effective solutions for large diameter pipe jacking with the ability to remove obstructions at the face

- Perform best in sand, medium to stiff clay, dry or dewatered soil, and weathered rock without groundwater

- EX‐50 Excavator interchangeable between EBS models

EBS 840

EBS 960

EBS 1080

EBS 1200

EBS 1440

Specifications

| Model | Shield OD | On-Board Power Pack | Excavator Controls |

|---|---|---|---|

| EBS 840 | 100-102 in. | Optional | EX-50 |

| EBS 960 | 114 in. | Optional | EX-50 |

| EBS 1080 | 128 in. | Standard | EX-50X |

| EBS 1200 | 144 in. | Standard | EX-50X |

| EBS 1440 | 168 in. | Standard | EX-50X |

Increase kits are available. Hydraulic Closeable Doors Optional on all diameters.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.