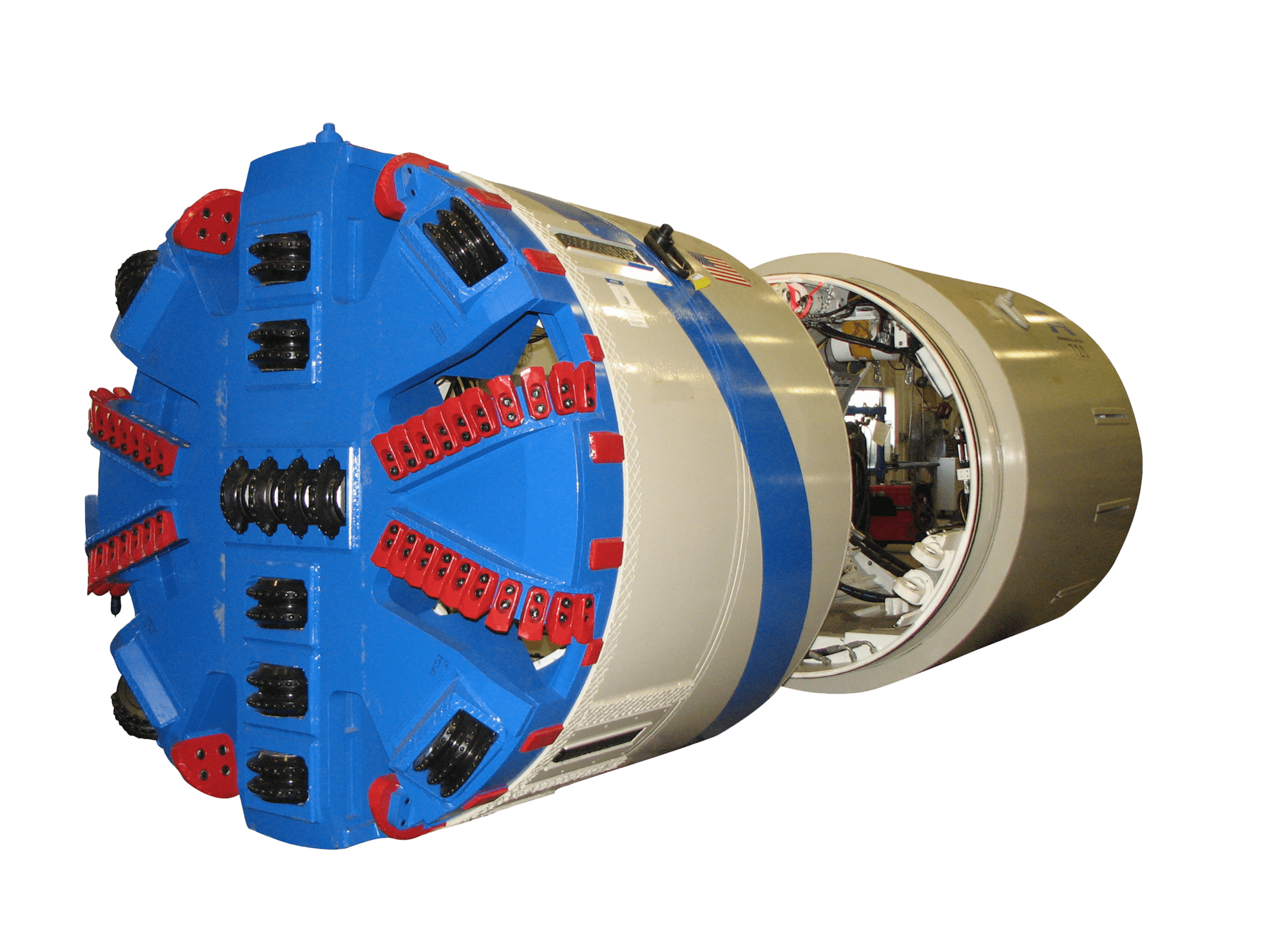

If you are in the trenchless industry, you are sure to be familiar with the legacy that Akkerman TBMs have created. While this time-tested and proven technology has been successfully installing thousands of tunnels around the world, we have been busy advancing the technology to maximize performance, expand capabilities, and increase versatility.

Features:

- TBMs can be used in pipe jacking or two-pass tunneling operation mode.

- Easy to operate. On-board manual control operation.

- Accurate and Reliable. Tunnel laser guidance with three-point sealed articulation.

- Interchangeable cutterhead. Standard cutter head is interchangeable underground if ground conditions change.

- Closed Face attachments and screw augers available for raveling ground.

- Disc Cutter Heads Available for rock up to 15,000 psi

- On-board methane gas detection system.

- Access to the face is readily available for obstruction removal.

- High capacity TBM bearing with powerful two-speed hydraulic drive system.

- Optional Earth Pressure Balance Mode to 1 bar.

- Increase kits are available for all TBM models. Akkerman will adjust diameters to match product pipe.

Tunnel Boring System

Specifications

| Model | Torque Max | TBM OD (Nominal) | Mode |

|---|---|---|---|

| WM48SC | 50,000 ft-lbf | 48 in | Open / Closed Face |

| WM420D | 53,000 ft-lbf | 51-52.5 in | Open / Closed Face |

| WM480D/II | 96,000 ft-lbf | 58-60 in | Open / EPB / Closed Face |

| WM540II | 111,000 ft-lbf | 65-66.5 in | Open / EPB / Closed Face |

| WM600II | 128,000 ft-lbf | 72-74 in | Open / EPB / Closed Face |

| WM720II | 240,000 ft-lbf | 86-88 in | Open / EPB / Closed Face |

| WM840II | 440,000 ft-lbf | 96-98 in | Open / EPB / Closed Face |

| WM960II | 550,000 ft-lbf | 114-116 in | Open / EPB / Closed Face |

- Increase kits are available.

- EPB Mode requires optional bulkhead kit.

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.