- Applications

- Methods

- Equipment

- View All Equipment

- Guided Boring

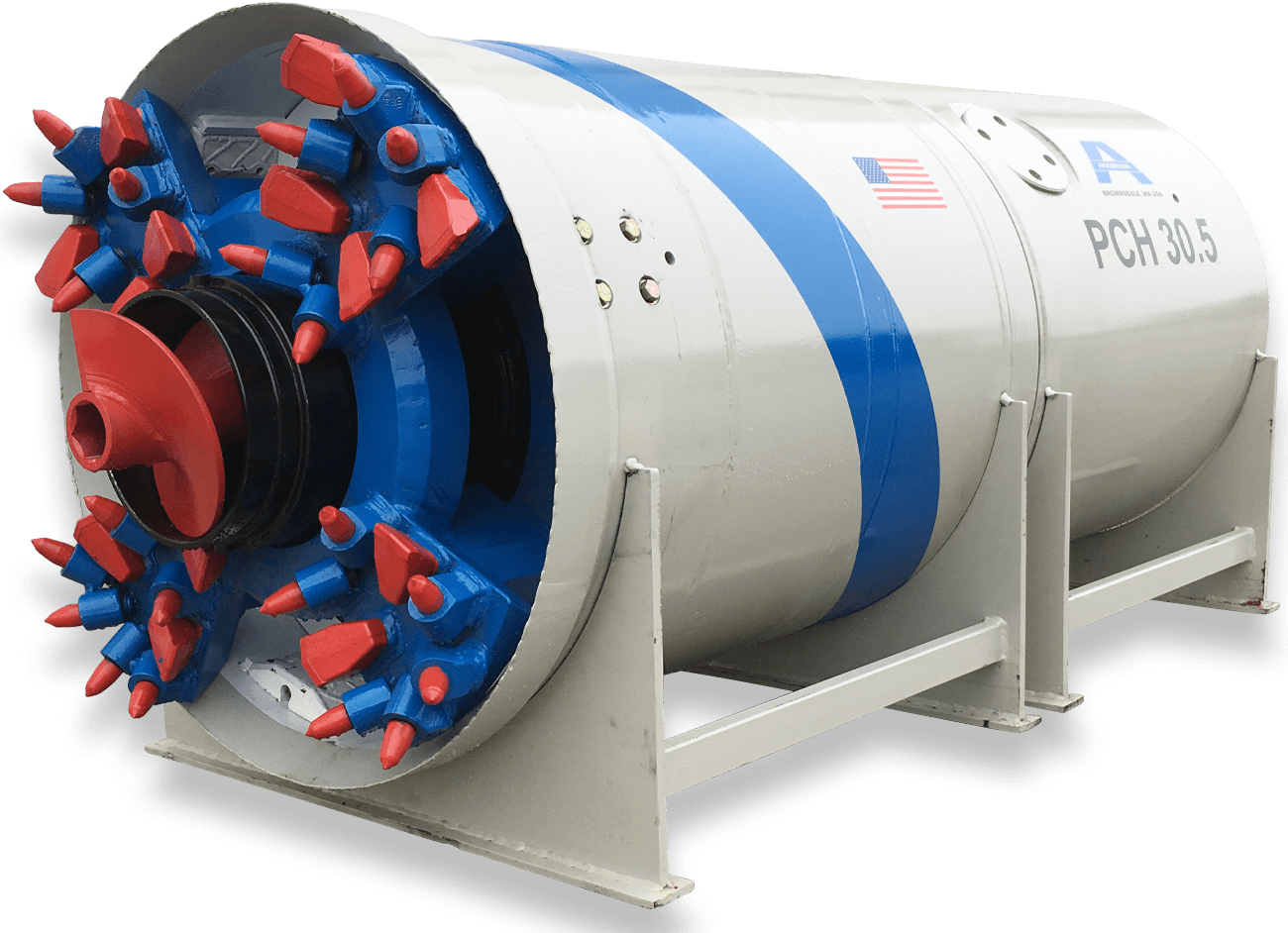

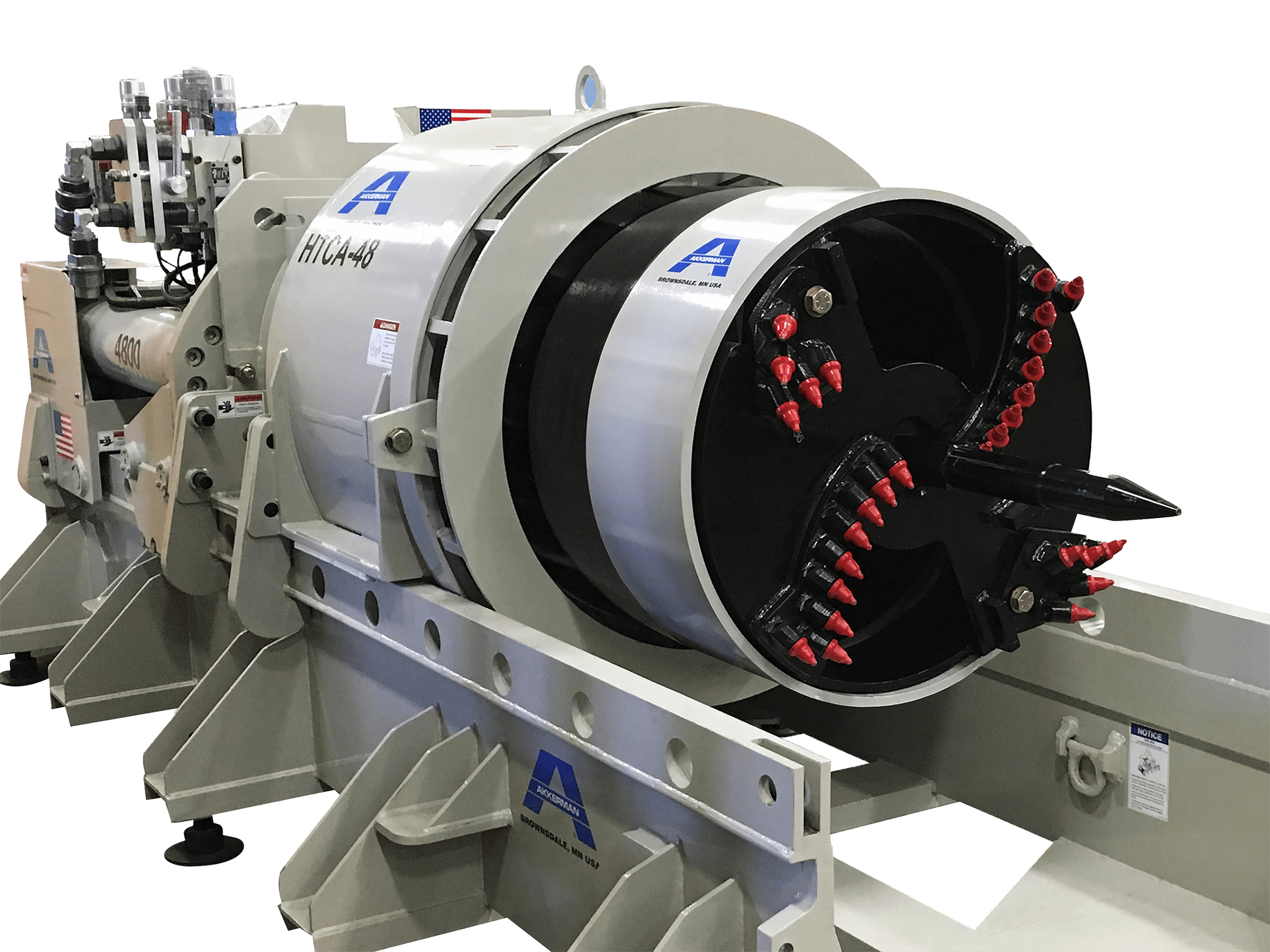

- Slurry Microtunneling

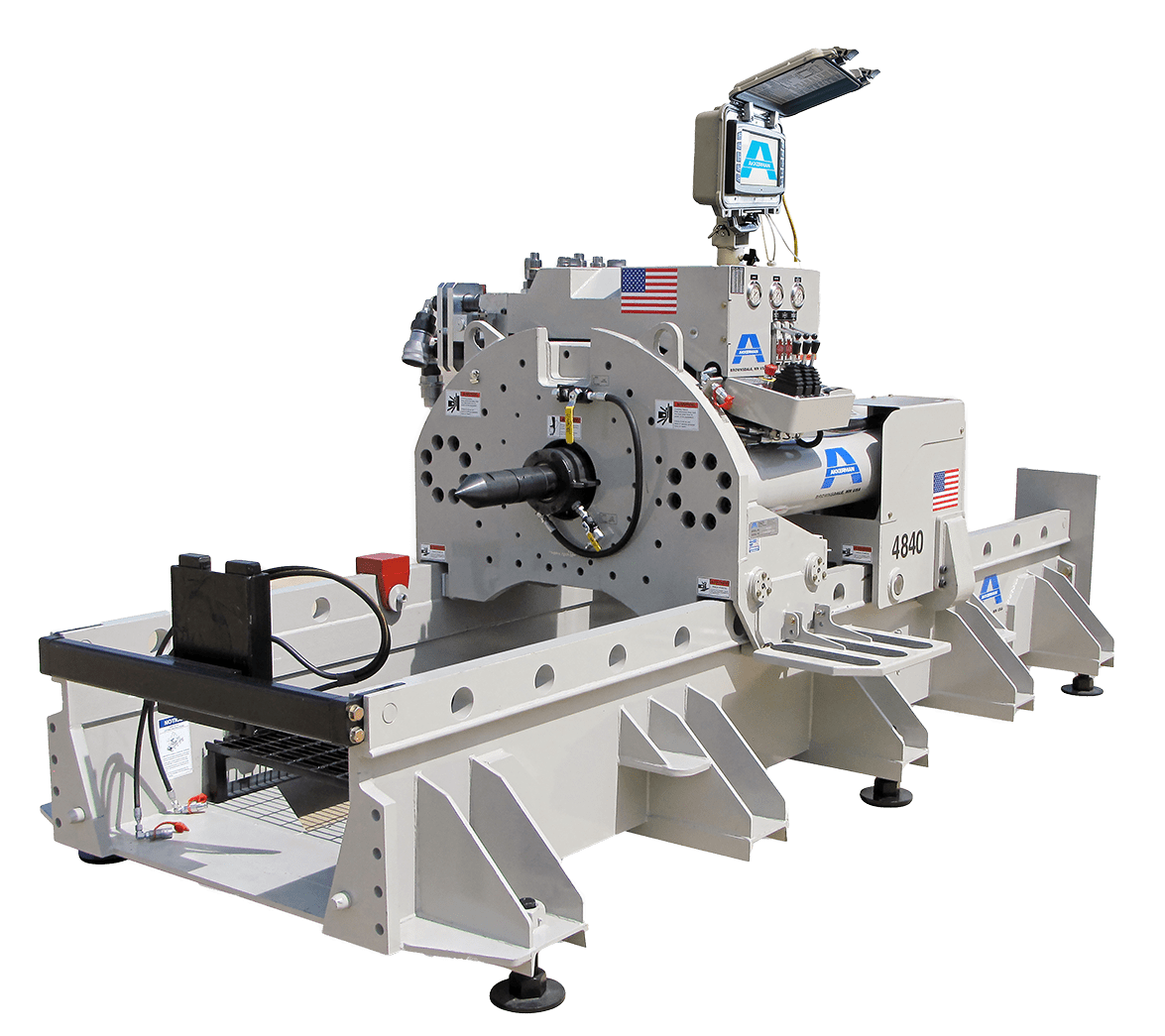

- SLC Series System – Center Drive

- SLP Series System – Periphery Drive

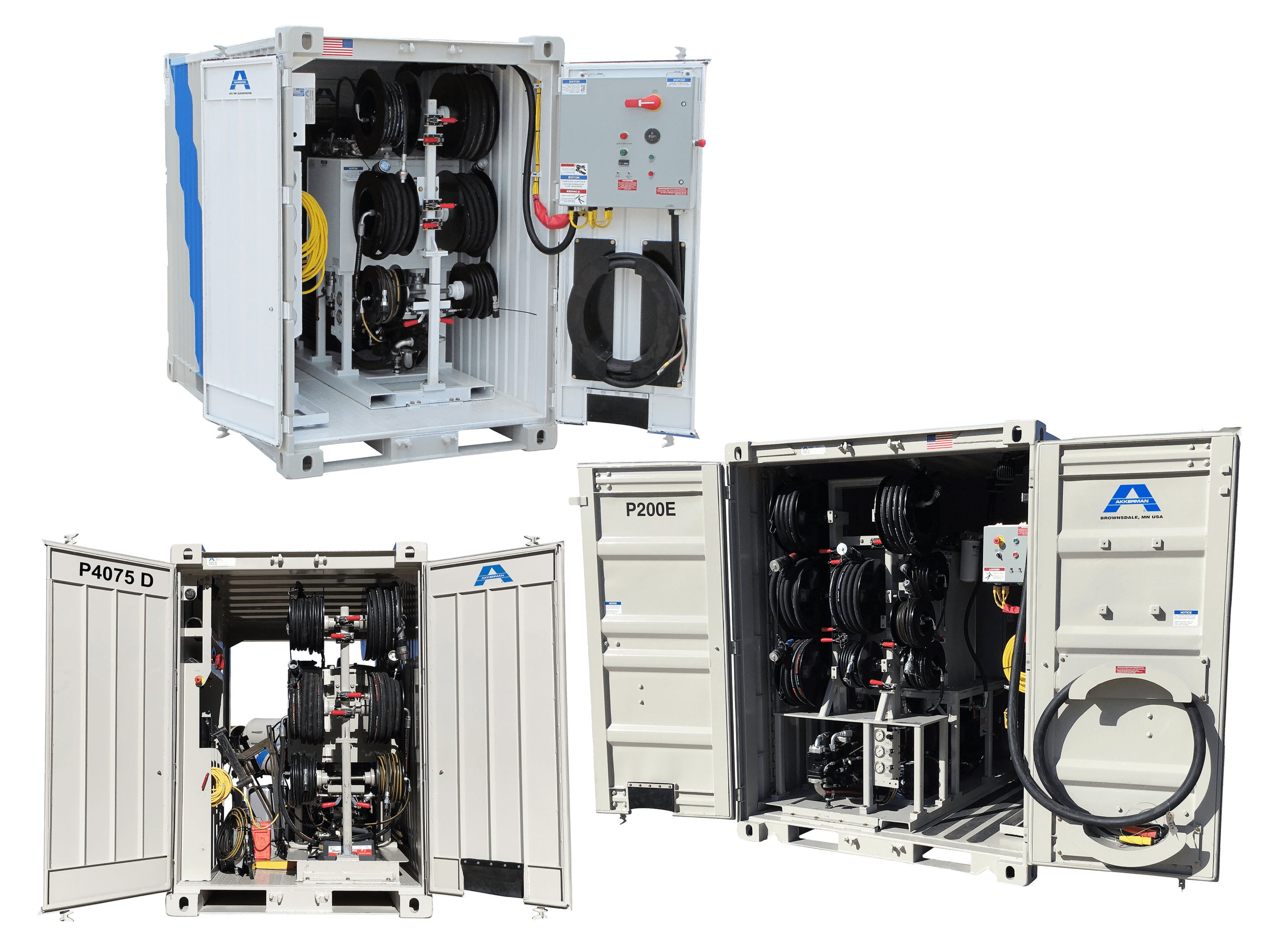

- Control Containers

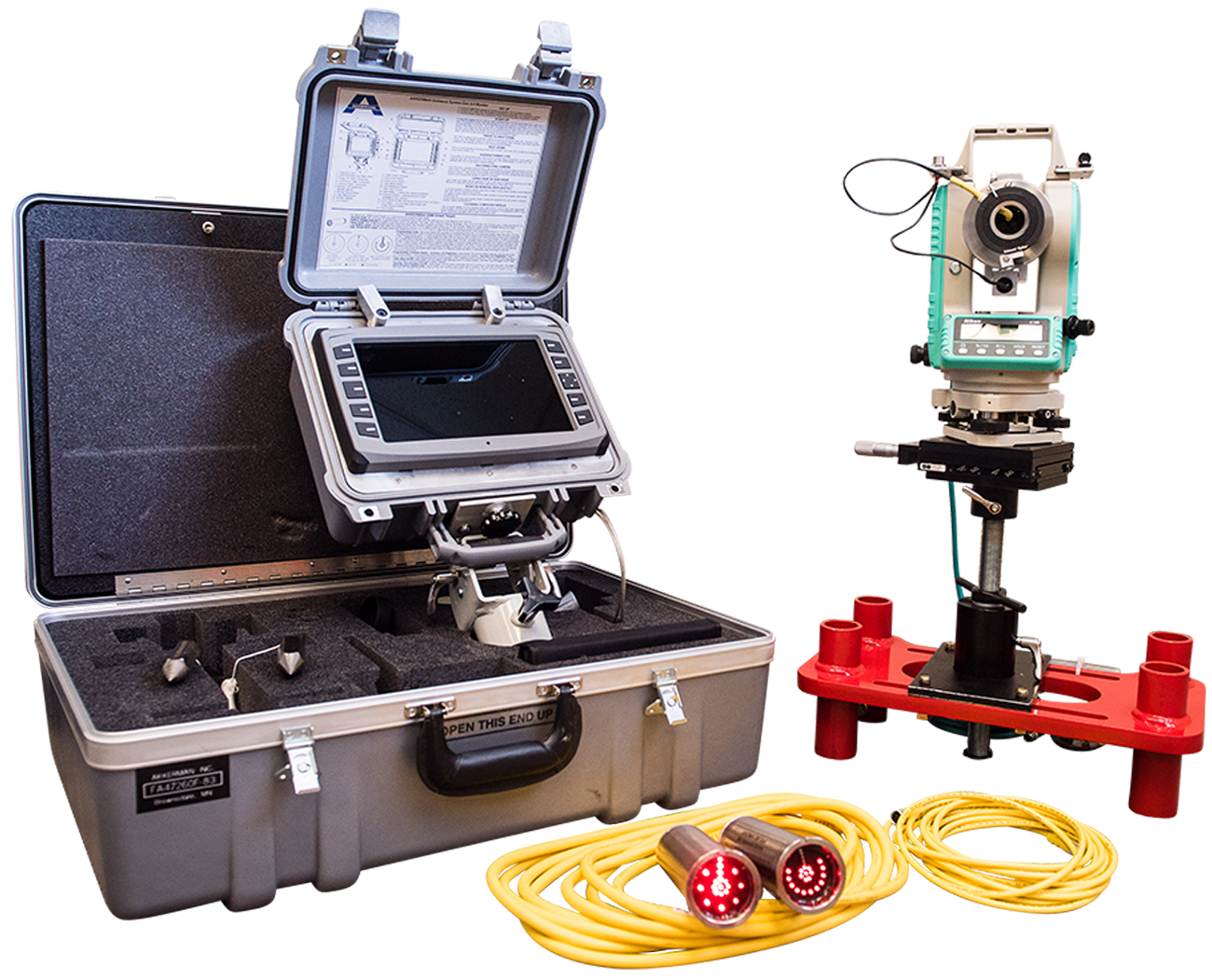

- MTBM Guidance System

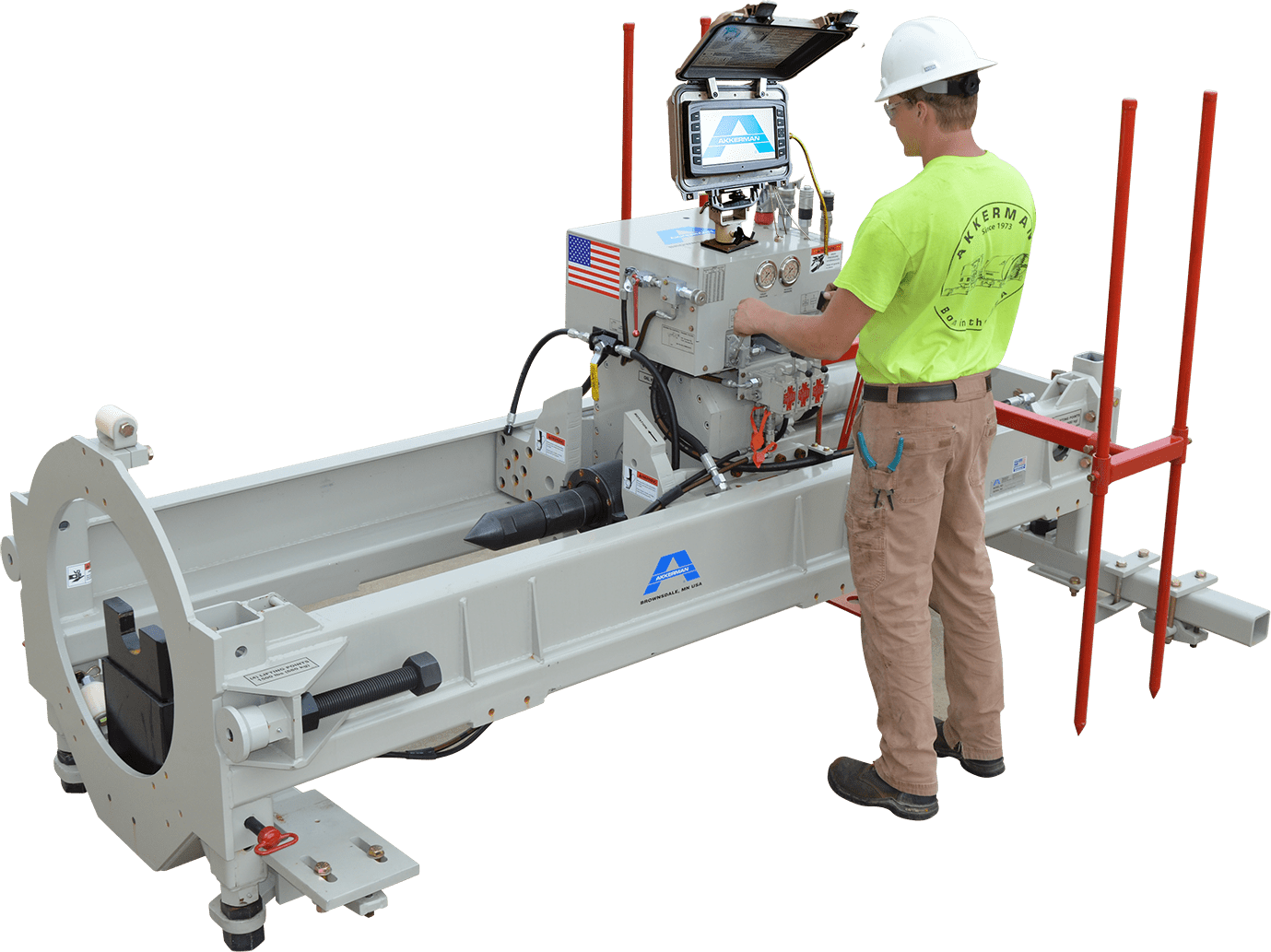

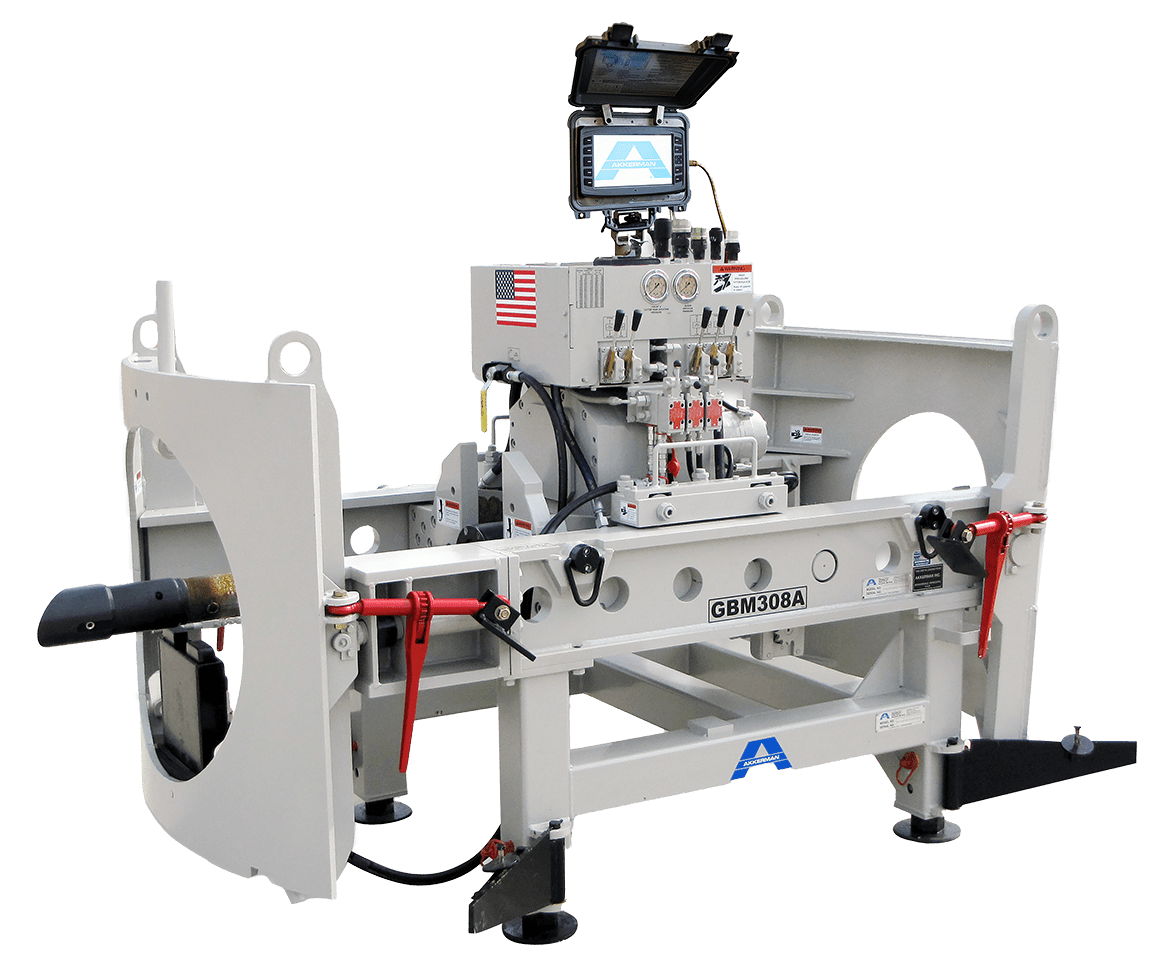

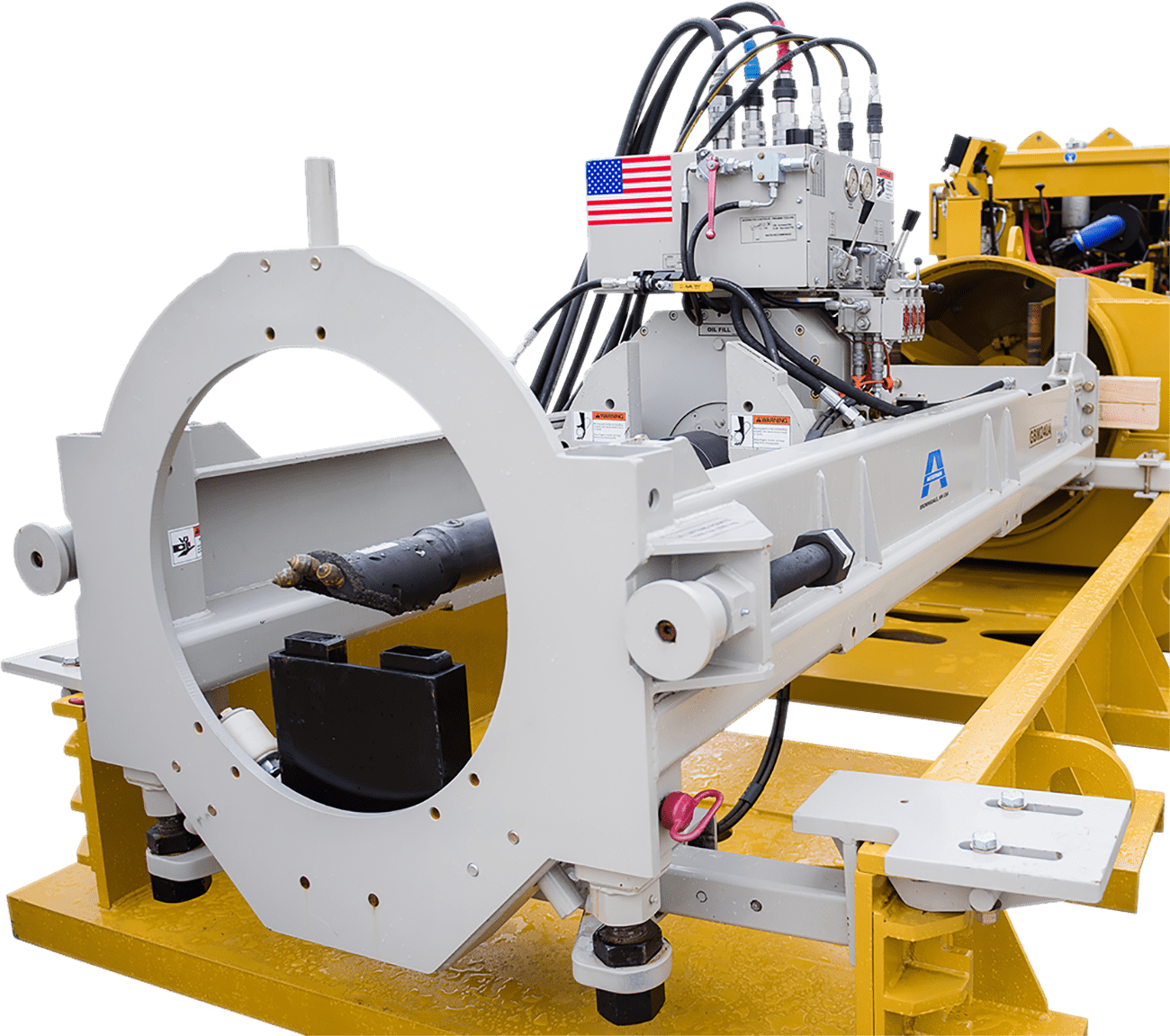

- MTBM Jacking Frames

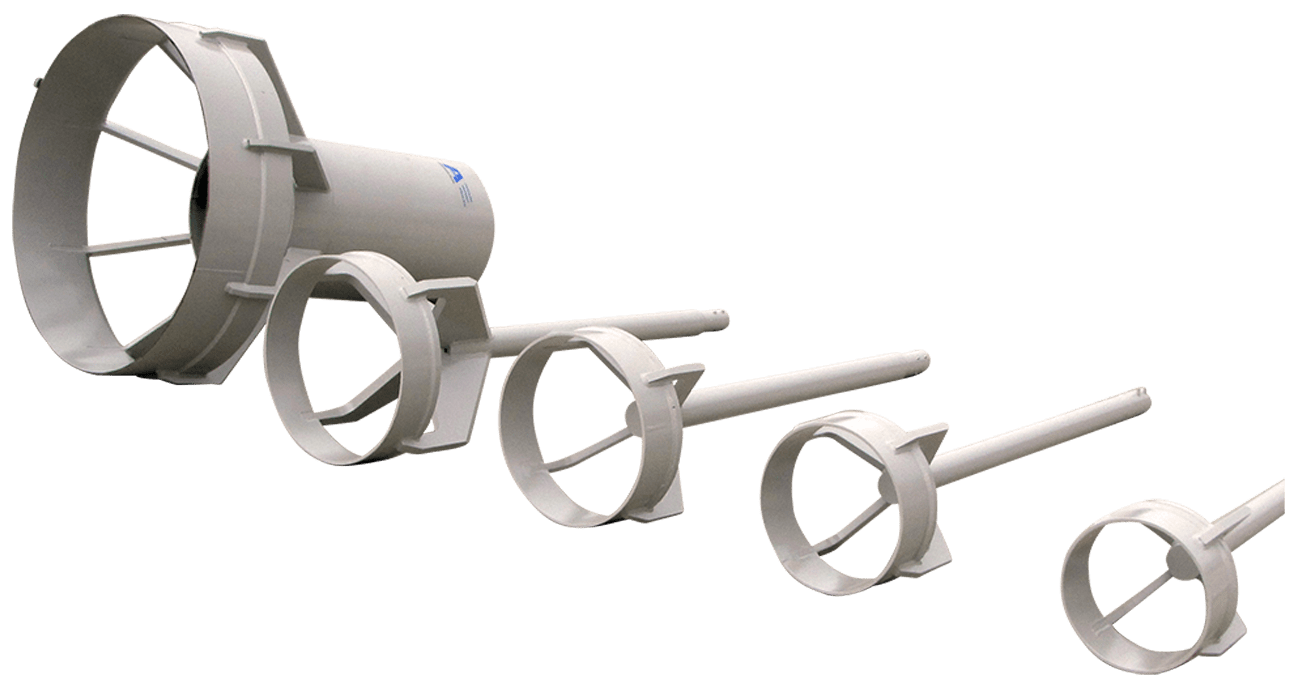

- MTBM Increase Kits

- MTBM Lubrication & Jacking Cans

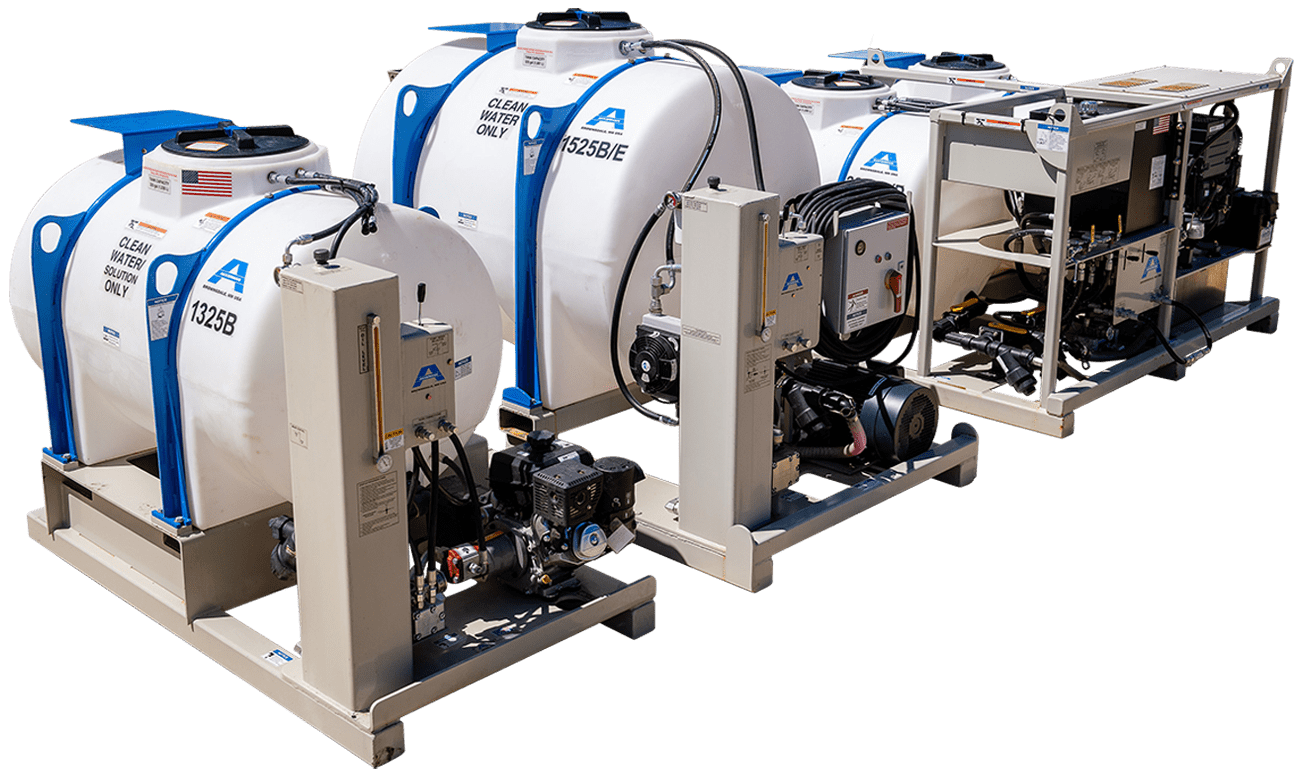

- Automated Bentonite Injection System

- MTBM Intermediate Jacking Stations

- Shaft Seals & Pipe Clamps

- Water Jetting & Cooling

- AZ100 Total Guidance System

- Pipe Jacking & Utility Tunneling

- Sliplining

- Lubrication Systems

- Support Equipment

- Case Studies

- Parts & Services

- Sales & Leasing

- Financing

- Contact