DIGGING DEEPER | AUGUST 2025

Guided Auger Boring: A Precision Approach to Trenchless Utility Installation

By: Jason Holden, Vice President, CRO – Akkerman Inc.

As infrastructure demands grow and surface disruption becomes less tolerable, guided auger boring (GAB) continues to gain traction as a reliable, accurate, and cost-effective trenchless solution. Frequently specified under the designation of Pilot Tube Guided Auger Boring (PTGAB), this method has become a preferred approach for utility owners and contractors alike when line and grade precision are non-negotiable.

Methodology Overview

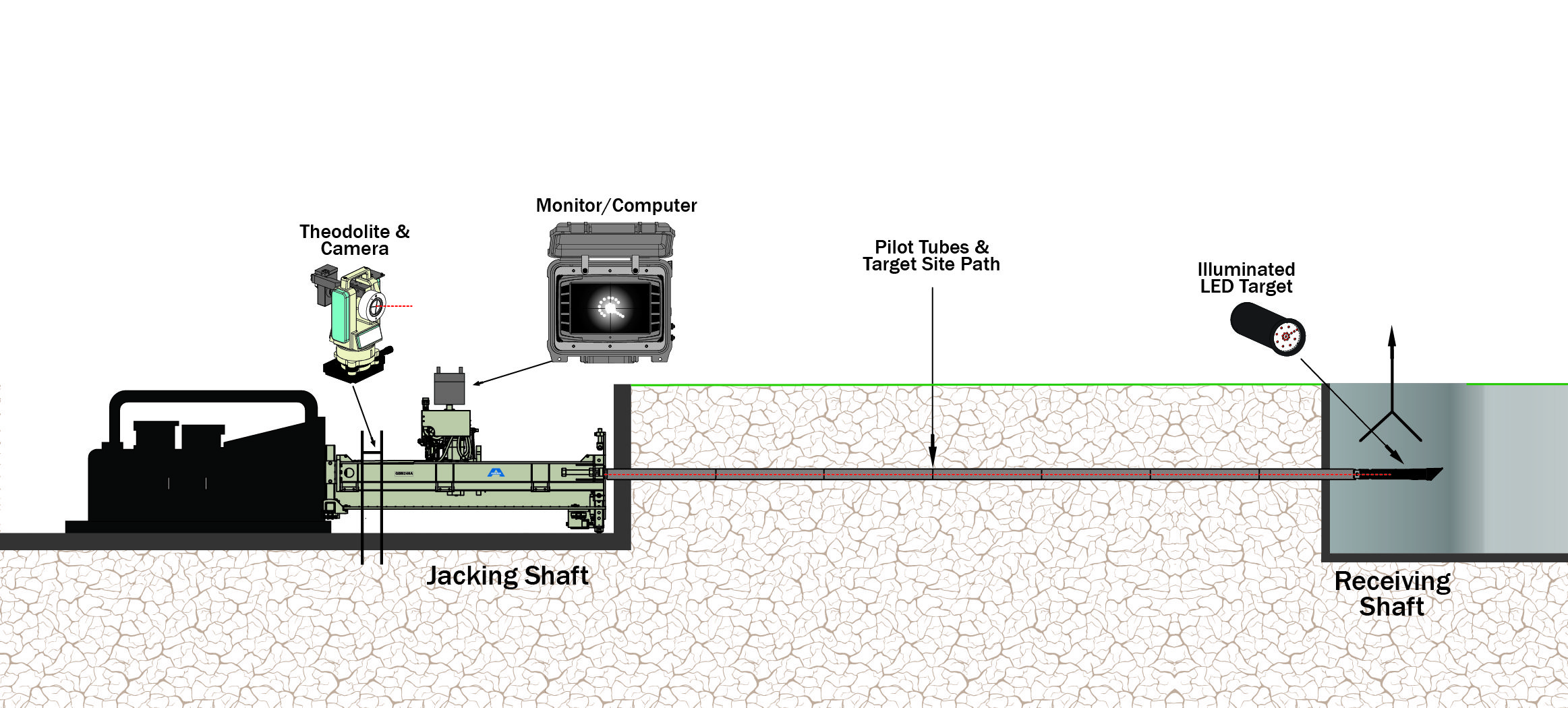

Guided auger boring combines two proven trenchless techniques—the Pilot Tube Method (PTM) and Auger Boring (AB)—to deliver a highly controlled installation of steel casing beneath roads, railways, and sensitive structures. The process begins with the installation of pilot tubes along a predetermined alignment using an optical guidance system. Once the pilot path is established, it is then upsized, and the casing is installed along the same path.

Figure 1: General Layout of Pilot Tube Installation.

This method blends the controlled accuracy of pilot tube installation with the proven strength of auger boring. Unlike conventional auger boring (jack-and-boring), guided systems can achieve line and grade accuracies within ±¼ inch over hundreds of feet. This level of control is particularly important when installations are grade critical, working near existing infrastructure, or within strict right-of-way boundaries.

Engineered for Accuracy and Adaptability

Akkerman’s guided boring systems are designed to meet the complex demands of trenchless utility installations. The 240A GBM system serves as a modular platform that accommodates a range of trenchless applications, including guided auger boring, guided pipe ramming, pilot tube microtunneling, probing, utility pull-back, and others.

A cornerstone of the system is its advanced optical guidance package, featuring a remote-controlled theodolite, LED target, and real-time digital feedback to the operator. This ensures precise pilot tube installation without requiring operator entry into the casing, supporting both safety and efficiency.

Figure 2: GBM Operator installing pilot tubes while monitoring guidance system.

In variable or reactive soil conditions, tooling options such as the triple-wall pilot tubes and lubrication pumping systems enhance installation performance. Triple-wall “spinner” tubes, for example, integrate a rotating shell that reduces torque and thrust, improving productivity in expansive clay soils.

Upsizing with Confidence

After pilot tube installation, a range of upsize tooling options allows the casing to be advanced accurately and efficiently. The redesigned HD Guide Rod Swivel (GRS) Cutterhead is one such innovation. Featuring a tapered profile for improved material flow and a high-strength interchangeable tooling system, the HD GRS Cutterhead is engineered for adaptability across a spectrum of soil types.

For casing diameters up to 42 inches OD, the GRS Cutterhead can be paired with a high-thrust bearing swivel that maintains alignment while minimizing wear. For larger diameters, an intermediate bearing swivel bridges the connection to ensure structural support during longer, more demanding bores.

Figure 3: Akkerman HD Guide Rod Swivel Cutterhead

Practical Advantages

Beyond its technical merits, guided auger boring offers several real-world advantages:

- Safety: Eliminates the need for personnel entry into the casing during pilot tube steering.

- Cost-Efficiency: Reduces social and economic costs through precise installations, minimized surface disruption, and reduces the casing diameter required to meet critical grade.

- Geotechnical Insight: Pilot tube advancement offers early identification of obstructions and changing soil conditions. Pilot tubes are often used to probe for obstructions on highly sensitive, large diameter TBM or slurry microtunnel crossings to pinpoint potential hazards prior to construction.

- Versatility: Applicable across a wide range of diameters (4–72 in OD) and adaptable for more complex ground conditions with the use of accessories such as rock drill adapters and pneumatic hammers.

Guided boring is more than a construction technique—it is a strategic approach to utility installation that aligns precision engineering with modern infrastructure demands. Akkerman’s systems and support services reflect decades of innovation and practical field experience, making them a trusted resource for contractors, engineers, and project owners alike.

As trenchless technologies continue to evolve, guided boring remains a cornerstone of reliable and efficient underground construction—delivering accuracy, minimizing risk, and setting the standard for quality installations.

See Us at The Utility Expo

Louisville, KY | October 7-9, 2025

This is the premier event for utility professionals, and we’re excited to showcase how Akkerman’s trenchless solutions continue to push the boundaries of underground construction. Stop by our booth to connect with Jon Valin and Chris Sivesind, explore our innovative equipment, and see firsthand how our solutions deliver precision, efficiency, and reliability for even the most challenging projects.

Don’t miss it—register for your tickets today!