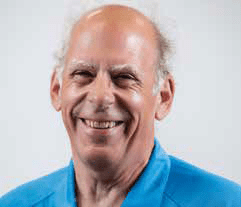

20th Akkiversary

While many of us will be enjoying holiday time with our family and friends, an important milestone will come to pass. On December 26, 2001, Terry Fisher joined Akkerman and, along with him, the expansion and 20-year history of success with the GBM product line.

Terry grew up on a farm and loved running equipment. He was aware of his aptitude for everything mechanical, electric, and hydraulic at an early age. After high school and following a series of odd jobs, he landed a position with Hydro AX in 1976. Hydro AX manufactured rubber-tired feller bunchers and other forestry equipment, and Terry helped build electrical and hydraulic assemblies.

In 1978, he assisted with designing and building their first disc-saw feller head prototype. He traveled to Thunderbay, ON, to conduct R&D with the unit and has been traveling since. Terry worked as a field technician for ten years and continued when Blount bought them out in 1989. He later began a position in new product development, then international sales support, product manager for track vehicles, then industrial sales before his career with them ended, with the sale of Blount.

Joining forces with a few of his Blunt cohorts – Randy Gasner, Mike Brooks, and Pete Moothart, Terry rounded out the Owatonna Mafia of Akkerman employees.

Terry was hired as the first product manager at Akkerman to accelerate GBM sales, working with Frank Lorenzen. Significant changes to the GBM equipment line soon transpired.

The first change was to redesign pilot tubes to a dual-wall design in his first year. The first GBM R&D project took place in January 2002 in Maryville, IN, on a Midwest Mole project with GBM 308 frame. Terry states, “It took two weeks to install 8-in. VCP pipe using single wall pilot tubes, and we couldn’t see the target past 180 feet”.

As better digital cameras became available, longer distances became feasible with less target loss. In his words, “We spent two years breaking things until we sold a system.” The first sale was in 2002, a 240-round back frame for 24-in. diameter pipe with an electric and diesel power pack to the EDC in Virginia.

In 2003, the P100Q was designed and represented outside-the-box innovation because its two independent jacking and rotation pumps helped performance and productivity.

He and Pete worked together to create specification sheets for our equipment, which never existed at Akkerman before.

The 2005 ICUEE Show unveiled the pilot tube system as a solution for guiding auger boring rigs to the market, which has been the most profitable to date.

GBM equipment systems have changed and diversified, but the initial goals remain the same – go further, faster, in harder ground. Terry reports, “When installing utilities for the Ikea store by the Mall of America, we used the two-pass method and were getting one pipe per hour at best.” Using the new powered cutter head design on a subsequent Gleason project, they could jack five, 1m pipes in an hour. Product line expansion snowballed from there.

Terry has traveled to 26 countries and all of the United States but Alaska throughout his career. One of his favored travel experiences was when he introduced the GBM 308 frame to TES in southern England in 2005. He reports, “Bohrtec’s BM400 wasn’t able to get through with their single-wall pilot tubes design, and we out-competed them”. He also has fond memories of a project in Bogota, Columbia, with Al Belden, supporting two GBM 4812 systems, where the technology was far ahead of any of their previous pipe installation experiences.

Overall, what Terry loves most about his two decades with Akkerman are, “Overcoming the next challenge – the job never gets stale and

is constantly evolving, even now with our rock tooling innovations.”

With over a half a million miles down 218 and four cars later, Terry’s still working hard to innovate the GBM product line. When you return from your holiday, be sure to remind Terry of what an asset he is to Akkerman and congratulate him on his Akkiversary.