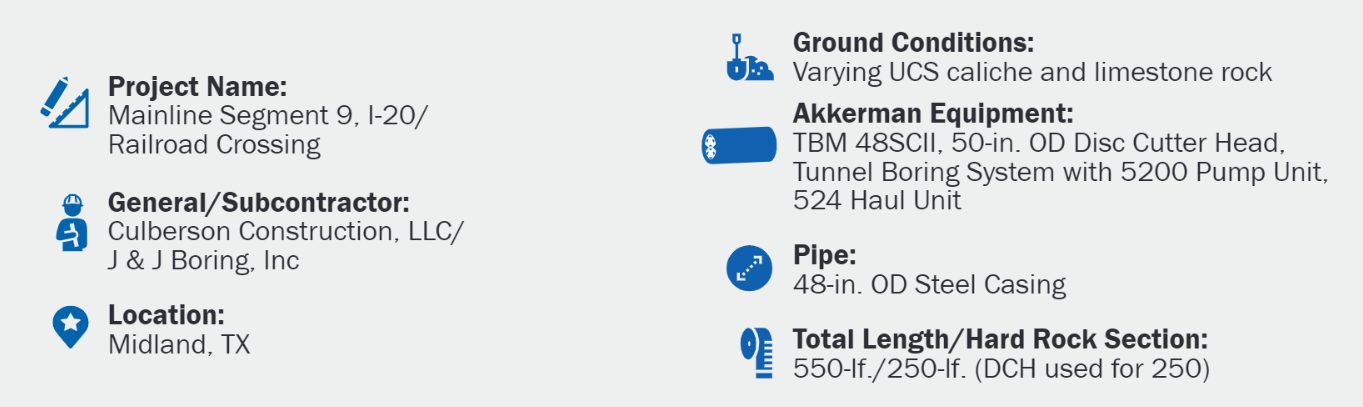

Mainline Segment 9 Project

Project Overview

The project involved the construction of a 36-in. diameter HDPE water line inside of a 48-in. diameter casing, that ran under highway I-20 and a Union Pacific Railroad near Stanton, TX.

While using their 48SCII TBM with standard carbide cutter head, J & J Boring, Inc. encountered rock conditions midway across the bore which were not stated in the pre-bid GDR. The unanticipated ground proved challenging to mine with the initial TBM cutter head setup. After a few worn tooling changes, the contractor decided to develop a better solution to mine the rock.

The Challenges

- Installation in hard caliche/limestone rock

- Crossing under active rail line and I-20 Highway

- Actual project rock rating was 40% harder than pre-project GDR indicated

- Hardest rock encountered within sensitive rail road Zone A, requiring 24-hour non-stop construction and no surface access

The Solution

Key benefits of owning an Akkerman TBM is the interchangeable cutter heads feature and the ability to access the face of obstruction removal. J & J Boring, Inc. contacted Akkerman for a Disc Cutter Head attachment for their 48SCII TBM to fracture the hard caliche and limestone rock into pieces while maintaining alignment despite geological variations.

The 48SCII TBM Cutter Head features:

- (16) 6.5-in. disc cutters, capable of 5 tons of thrust each

- Cutter head rock scrapers assist in transferring cuttings away from the face, to the conveyor, then to the haul unit for removal from the tunnel

- Heavy-duty bearing to handle disc thrust loads

- Recommended Uni-directional operation for effective mining

The lead 48-in. casing was welded to the TBM to counteract the rotational torque necessary to mine the rock with uni-directional cutter head. The operators monitored the thrust loads on the cutters to ensure they did not become overloaded.

Outcome

- J & J Boring, Inc. completed the drive in challenging rock that would have been otherwise improbable

- No cutter head tooling replacements required

- Mid-project rock testing indicated project rock samples of 13,000 PSI UCS.