5th Akkiversary

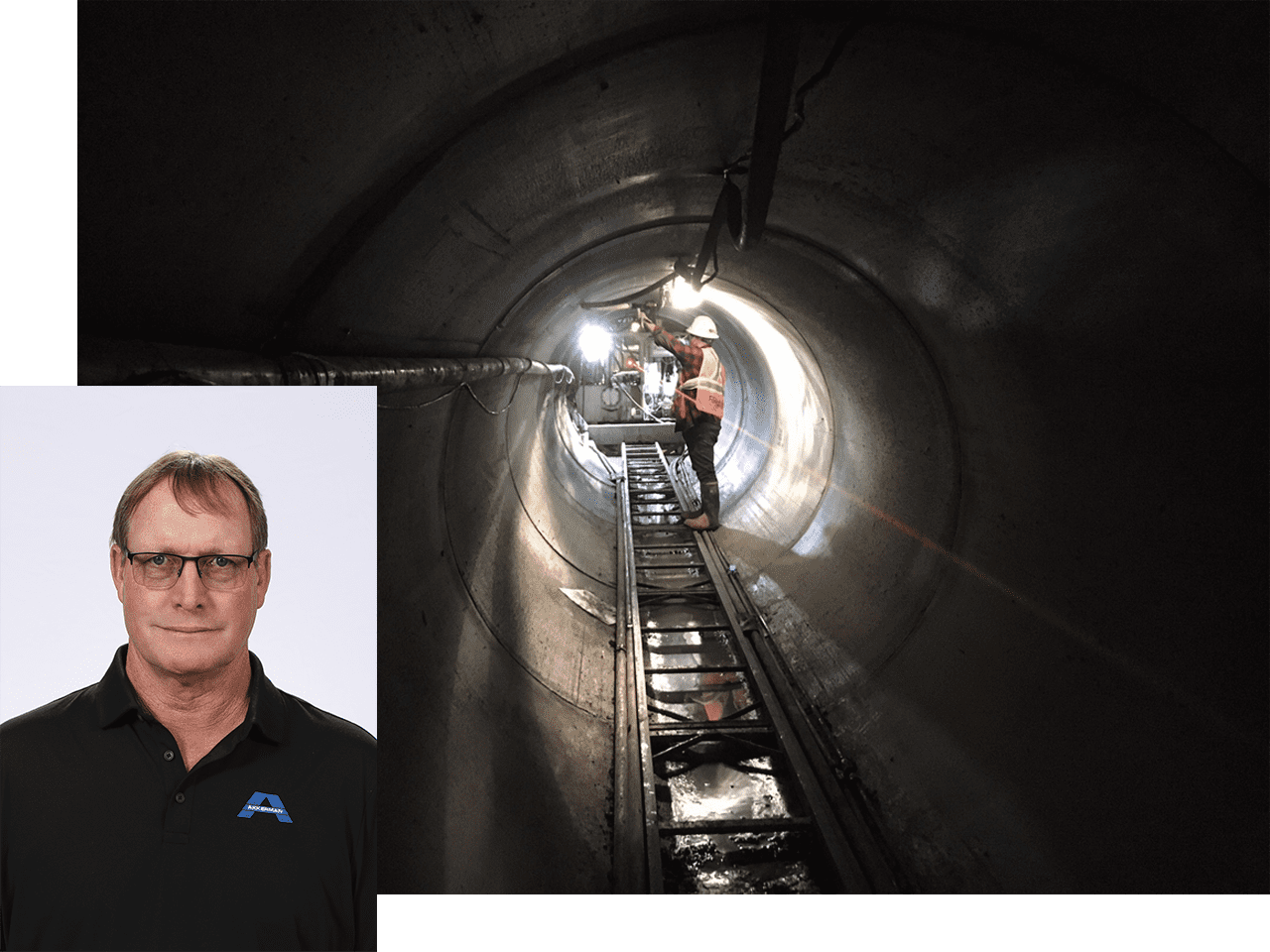

Paint manager Ben Wolcott began as a night shift painter with Akkerman on February 12, 2019. We are celebrating Ben’s fifth year of working at Akkerman this month.

After high school Ben pursued a degree in collision repair with Riverland Community College. He started his industrial painting career with McNeilus Truck in Dodge Center, then was employed as board operator by Absolute Energy in St. Ansgar.

Ben was referred to Akkerman by his mother-in-law, Mary Hartson. As existing painter Jeff Hall was approaching retirement, hiring Ben was an excellent opportunity to bring his expertise to Akkerman while training under Jeff and maximizing the department’s production on two shifts. Jeff retired about two years into Ben’s employment then Ben moved to the day shift and paint manager position.

When asked what he enjoys most about this work, he likes the challenge of making each piece of equipment look smooth, consistent, and finished. Ben enjoys working for Akkerman, the environment, and his colleagues. “The company treats you well, and there’s a nice family environment,” he comments.

Ben and his wife Hannah reside in Lyle, MN, with their three daughters, Jadyn (6), Iylah (4), and Emilia (4 mo.). Ben likes spending family time at Mary’s and Mike’s cabin, relaxing and jet-skiing. He’s also a big motocross enthusiast and hopes to get his oldest two daughters on bikes this year.

When you see Ben, congratulate him on his anniversary and thank him for all his hard work and attention to our equipment’s aesthetics.