Temporary Thrust Casing and Auger assemblies are positioned directly behind a reaming head, which follows the pilot tubes. The reaming head increases the bore diameter, and the augers transport spoil to the launch shaft.

The Integral Bearing Swivel Cutter is an upsizing tool between the pilot tube adapter and the lead thrust casing. It is used in ground conditions above 35 blow count and functions to keep the pilot tubes stationary. Simultaneously, the cutter bit rotates to excavate the soil, and fluid ports release lubrication to reduce cutting torque. Integral Bearing Swivel Cutters are available in standard and HD models to match the thrust casing assemblies.

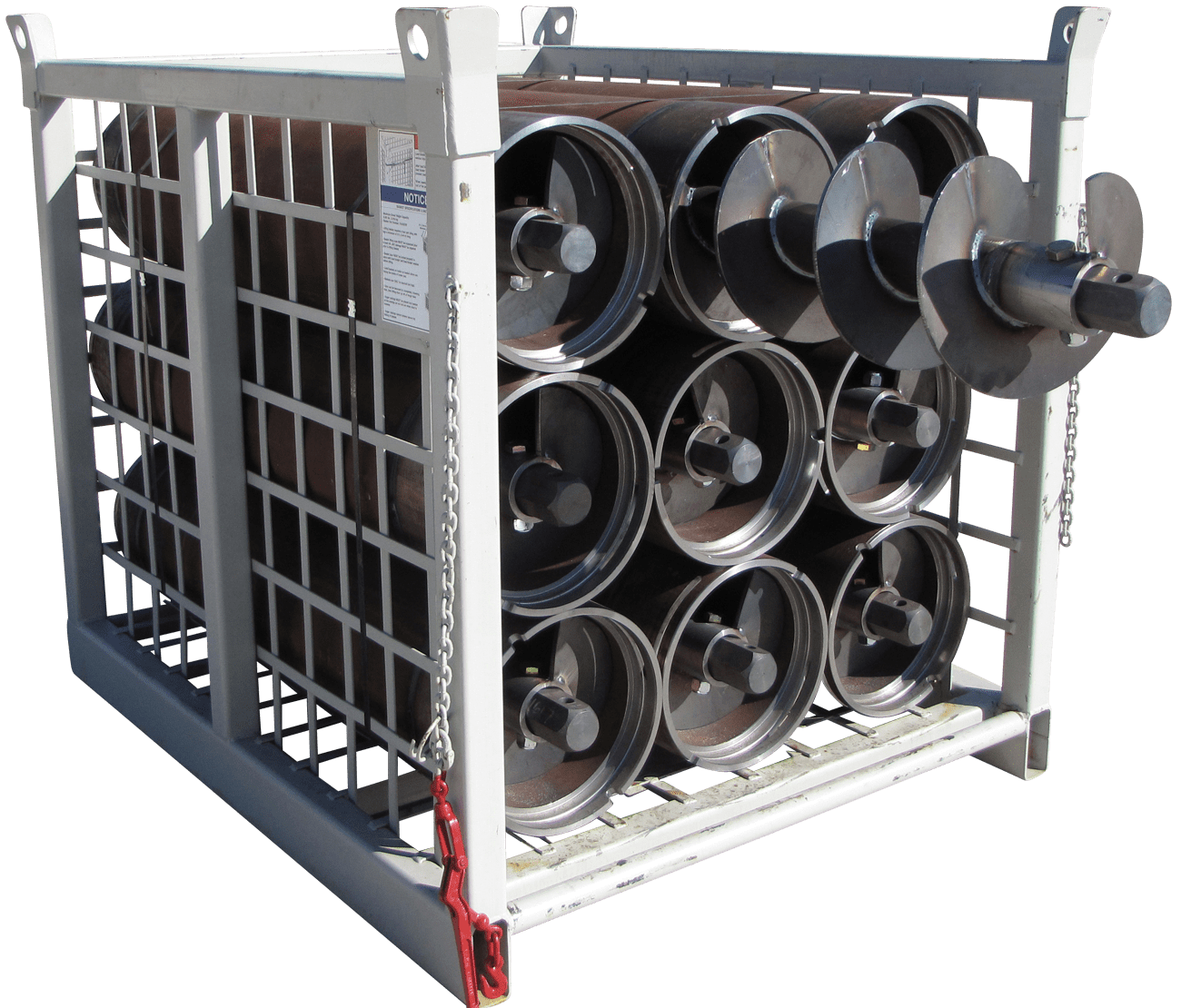

Thrust Casing & Auger Assemblies Features:

- Available in 11, 16‐in. OD standard and 16‐in. OD Heavy Duty

- Casings connect with retaining clips

- Supplied in a convenient wire basket for ease in transport

Integral Bearing Swivel Cutter Features:

- Mates to lead thrust casing assembly

- Used in ground condition above 35 blow count

- Absorbs the rotation of the augers to keep pilot tube string stationary

- Cutter bit tooling excavates the ground

- Cutter bit fluid ports to release lubrication to reduce cutting torque

11‐in. Thrust Casing and Auger Assembly

16‐in. Thrust Casing and Auger Assembly

16‐in. HD Thrust Casing and Auger Assembly

Integral Bearing Swivel Cutter 11‐in.

Integral Bearing Swivel Cutter 16‐in. HD

Specifications

Thrust Casing and Auger Assembly

| Model | Length | Max. Thrust / Torque | Weight Ea. |

|---|---|---|---|

| 11 in. | 1 m | 100 ton / 10,500 ft‐lb | 265 lbs |

| 16 in. | 1 m | 100 ton / 10,500 ft‐lb | 400 lbs |

| 16-in. HD | 60 in | 200 ton / 21,000 ft‐lb | 570 lbs |

| 11 in SCH | 43 in | 70 ton / 10,500 ft-lbf | 700 lbs |

| 16 in SCH | 43 in | 100 ton / 21,000 ft-lbf | 1,200 lbs |

Testimonials

Mextune / Group S de RL de CV

In recent years we have acquired different spare parts for our Akkerman brand TBMs, which have allowed us to have the equipment ready. We have used our tunnel boring machines in 2 emergency projects recently:

- Completion of the construction of the El Valle Collector, with reinforced concrete pipe of 2.13 meters inside diameter for the municipality of Tlajomullo de Zuniga Jalisco.

- Construction of the Jamapa Collector in the municipality of Ecatepec de Morelos (New construction). With 1.22m RCP pipe.