Akkerman

depthS of innovation

Akkerman is a global leader in underground boring solutions, delivering precision-engineered trenchless technology to projects worldwide. With decades of expertise and a reputation for innovation, Akkerman has successfully partnered with contractors in Australia, India, Israel, and beyond to tackle complex tunneling challenges. Our commitment to quality, efficiency, and client success makes us the trusted choice for trenchless solutions that drive infrastructure forward.

Methods

Pilot Tube

The Pilot Tube Method (PTM) is a highly accurate trenchless technique for installing gravity flow sewer pipes, integrating features from methods like microtunneling and auger boring. It achieves precision within +/- 1 inch of grade and +/- 3 inches of alignment, with typical drive lengths of 400 feet or less, and is suitable for displaceable soils or challenging conditions with additional tooling.

Auger Boring

Horizontal auger boring, or jack-and-bore, is a trenchless method for installing steel casing using a rotating cutterhead and augers to excavate and remove material in various non-pressurized ground conditions. Akkerman’s guided systems provide exceptional accuracy and are compatible with leading equipment manufacturers, offering complete solutions for guided and un-guided installations.

Tunnel Boring

Tunnel boring uses a cutterhead to excavate utility tunnels with precision, guided by a tunnel laser, and is suitable for gravity flow installations in non-pressurized ground to weathered rock up to 15,000 psi UCS. Typical drive lengths range from 400 to over 1,000 feet, depending on the method (pipe jacking or two-pass mode), ground conditions, and diameter.

Sliplining

Sliplining is a cost-effective pipe rehabilitation method that inserts a new liner pipe into a deteriorated pipeline to extend its lifespan and improve flow, often without service disruptions or bypass pumping. This remotely operated process ensures safety and efficiency, with productivity rates of 1-2 feet per minute and advanced data logging for performance monitoring.

Equipment

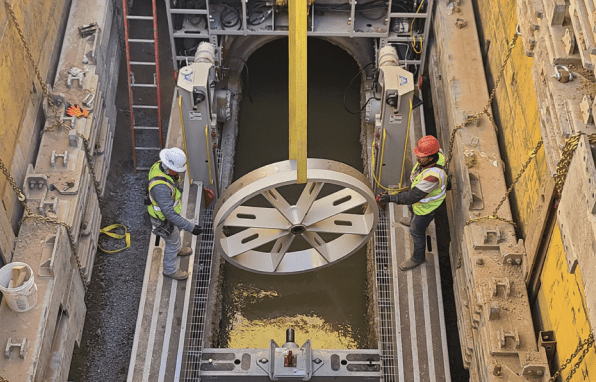

Akkerman offers a range of advanced equipment designed to meet the demands of trenchless infrastructure projects worldwide. The SLS-100 Sliplining System provides an efficient and cost-effective solution for rehabilitating failing pipelines, accommodating 30-102-inch OD pipes with modular frames that support up to 20-foot joints. It eliminates the need for bypass pumping and ensures precision using a wireless remote controller with LCD functionality to operate the main drive, brakes, and pipe positioning systems.

Additionally, the Guided Boring delivers unmatched accuracy for precise pipe installations in various ground conditions, while Pipe Jacking & Utility Tunneling provides reliable systems for larger-diameter utility tunnels. These versatile solutions ensure durability, precision, and efficiency for international trenchless projects.

Meet Your Sales Team

Case Studies

TUNNEL BORING

PIPE JACKING & UTILITY TUNNELING

The project involved installing a 36-inch HDPE water line beneath I-20 Highway and a Union Pacific Railroad near Stanton, TX… Unexpected hard rock posed challenges, but J & J Boring, Inc. used a customized TBM to complete the bore…

TUNNEL SLIPLINING

TUNNEL SLIPLINING A SUCCESS

The project upgraded San Diego’s aging aqueduct using sliplining technology to improve reliability, overcoming access and environmental challenges through meticulous planning and teamwork…

SLIPLINING

3rd Street Sewer Rehabilitation

This case study demonstrates sliplining technology’s efficiency in rehabilitating aging infrastructure, overcoming challenges to ensure timely completion and uninterrupted services…

SLIPLINING

Q Line South Sliplining

The Q Line South project used sliplining to rehabilitate aging wastewater infrastructure in Israel, overcoming live flow challenges to complete on time and set a national installation record…

ROCK BORING

Oregon St. Sewer & Pump Station Upgrade

The Oregon St. project in Oshkosh, WI, used an Akkerman RBU 36 to install a 36-inch steel casing under an active rail line through hard dolomite rock. Despite challenging conditions, the drive was completed successfully…

AUGER BORING

RISING TO NEW HEIGHTS WITH GUIDED BORING

The case study highlights the successful use of guided boring methods to overcome challenging ground conditions, improve utility infrastructure, and ensure precise installations with minimal disruptions…