Guided Auger Boring Tooling for Hard Ground – Upsize Bearing

Pilot Tube Guided Auger Boring (PTGAB) remains one of the most common trenchless applications in North America for the installation of underground utilities requiring exact line and grade tolerances. Manufacturers such as Akkerman continually seek ways to improve performance and efficiency for trenchless contractors.

Decades ago, pilot tube installations were limited to displaceable ground conditions and short crossings. Today, contractors are utilizing pilot tube systems to conquer increasingly difficult projects including hard rock with the use of guided DTH hammers. Options for increasing the borehole diameter after the pilot tube installation in soft grounds are well established with common Weld-On Reaming Heads, however effectively upsizing beyond 36-in steel casing in stiff, non-displaceable ground, and rock require alternative solutions.

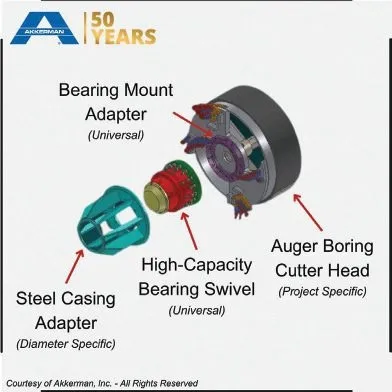

As an industry recommendation, steel casing up to 36-in OD can generally be directly linked to a pilot tube string. Larger casing installations require a two-step process to minimize deviation and ensure line and grade tolerance. The general rule-of-thumb has been to install an initial steel casing directly behind the pilot tubes that is approximately ½ the diameter of the final diameter. As ground conditions transition from soft to hard, it becomes important for the leading edge of the upsize tooling to engage the ground with a cutting action versus displacement arms.